Welcome to our online store!

Feb . 10, 2025 10:26

Back To List

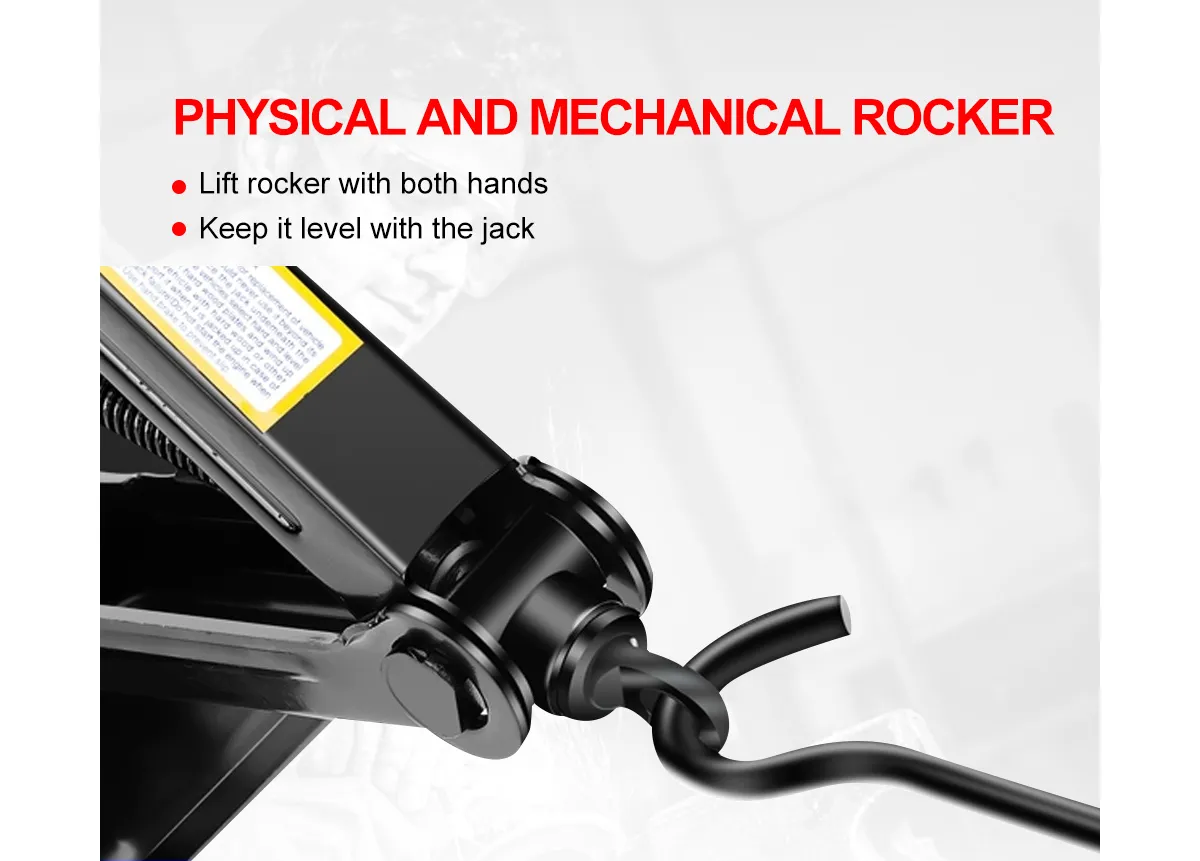

Heavy Duty Vehicle Support Car Jack Stand 3T 6T Adjustable Mobile Jack Stand

Elevating a vehicle safely for maintenance or repair is a fundamental aspect of automotive care, where the jack stand plays an indispensable role. For vehicle owners and auto mechanics, understanding how to effectively use a jack stand under a car is pivotal to ensuring safety and efficiency in vehicle maintenance.

In terms of expertise, knowing the types of jack stands can greatly influence the task's success. Pin-lock jack stands offer precise height adjustments, while ratchet-type stands provide quick setup and additional flexibility for varied vehicle types. Each design requires an understanding of its mechanical operation to ensure it locks securely under load. For trusted authority in jack stand usage, one should follow manufacturer guidelines and ASE-certified mechanic recommendations. These professionals bring a wealth of experience, emphasizing the importance of maintaining jack stand equipment. Regular inspections for rust, structural integrity, and functionality prevent potential malfunctions. It's crucial to never exceed the height or weight limits specified by the manufacturer, as this could compromise safety. Additionally, authenticating the quality and credibility of the jack stands is necessary. Opt for products that meet ANSI or ASME standards, which are indicators of rigorous testing and safety compliance. User reviews and expert testimonials act as reliable sources when evaluating the best products available in the market. Engaging in vehicle maintenance with jack stands not only demands the right tools but also a commitment to learning and applying industry-standard safety practices. By combining a practical understanding of the equipment with authoritative advice, vehicle owners and mechanics can achieve both safety and efficiency, establishing a trustworthy routine that extends the life and performance of their automotive investments.

In terms of expertise, knowing the types of jack stands can greatly influence the task's success. Pin-lock jack stands offer precise height adjustments, while ratchet-type stands provide quick setup and additional flexibility for varied vehicle types. Each design requires an understanding of its mechanical operation to ensure it locks securely under load. For trusted authority in jack stand usage, one should follow manufacturer guidelines and ASE-certified mechanic recommendations. These professionals bring a wealth of experience, emphasizing the importance of maintaining jack stand equipment. Regular inspections for rust, structural integrity, and functionality prevent potential malfunctions. It's crucial to never exceed the height or weight limits specified by the manufacturer, as this could compromise safety. Additionally, authenticating the quality and credibility of the jack stands is necessary. Opt for products that meet ANSI or ASME standards, which are indicators of rigorous testing and safety compliance. User reviews and expert testimonials act as reliable sources when evaluating the best products available in the market. Engaging in vehicle maintenance with jack stands not only demands the right tools but also a commitment to learning and applying industry-standard safety practices. By combining a practical understanding of the equipment with authoritative advice, vehicle owners and mechanics can achieve both safety and efficiency, establishing a trustworthy routine that extends the life and performance of their automotive investments.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025