Welcome to our online store!

Gen . 16, 2025 01:15

Back To List

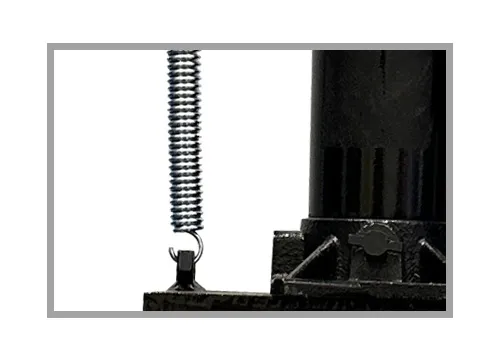

porta power repairs

Porta power tools are indispensable in various industries, where hydraulic force is needed to lift, push, or manipulate heavy objects. However, like any other mechanical tool, these devices require regular maintenance and occasional repairs to function efficiently. Understanding the nuances of porta power repairs can enhance the longevity and effectiveness of these tools, minimizing downtime and ensuring reliable operation.

Documentation and record-keeping play a significant role in effective porta power maintenance. Maintaining detailed records of inspections, repairs, and part replacements helps in tracking the tool's history and performance trends. This information is valuable for planning future maintenance and identifying recurring issues that could indicate underlying problems. Businesses should implement a comprehensive record-keeping system to enhance accountability and streamline the repair process. In addition to professional repair services, fostering a culture of preventive care among users can significantly reduce repair frequency. Training sessions on proper handling and regular maintenance procedures empower users to avoid common mistakes that lead to equipment damage. Encouraging feedback from users can also provide insights into potential issues that might not be evident during routine inspections. Finally, innovation in repair techniques and tools continues to evolve, making repairs more efficient and less time-consuming. Employing the latest repair technologies and methodologies can improve repair outcomes significantly. Staying abreast of these advancements ensures that repair professionals remain at the forefront of the industry, providing solutions that are both innovative and effective. In conclusion, maintaining and repairing porta power tools involves a combination of expert knowledge, attention to detail, and the use of quality parts and processes. Prioritizing these aspects not only extends the life of the equipment but also bolsters the trust placed in them by professionals who rely on their performance daily. Whether through professional interventions or user-driven maintenance practices, the pursuit of excellence in porta power repairs underpins a commitment to safety, efficiency, and reliability.

Documentation and record-keeping play a significant role in effective porta power maintenance. Maintaining detailed records of inspections, repairs, and part replacements helps in tracking the tool's history and performance trends. This information is valuable for planning future maintenance and identifying recurring issues that could indicate underlying problems. Businesses should implement a comprehensive record-keeping system to enhance accountability and streamline the repair process. In addition to professional repair services, fostering a culture of preventive care among users can significantly reduce repair frequency. Training sessions on proper handling and regular maintenance procedures empower users to avoid common mistakes that lead to equipment damage. Encouraging feedback from users can also provide insights into potential issues that might not be evident during routine inspections. Finally, innovation in repair techniques and tools continues to evolve, making repairs more efficient and less time-consuming. Employing the latest repair technologies and methodologies can improve repair outcomes significantly. Staying abreast of these advancements ensures that repair professionals remain at the forefront of the industry, providing solutions that are both innovative and effective. In conclusion, maintaining and repairing porta power tools involves a combination of expert knowledge, attention to detail, and the use of quality parts and processes. Prioritizing these aspects not only extends the life of the equipment but also bolsters the trust placed in them by professionals who rely on their performance daily. Whether through professional interventions or user-driven maintenance practices, the pursuit of excellence in porta power repairs underpins a commitment to safety, efficiency, and reliability.

Prev:

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025