Welcome to our online store!

Feb . 17, 2025 17:35

Back To List

10t shop press

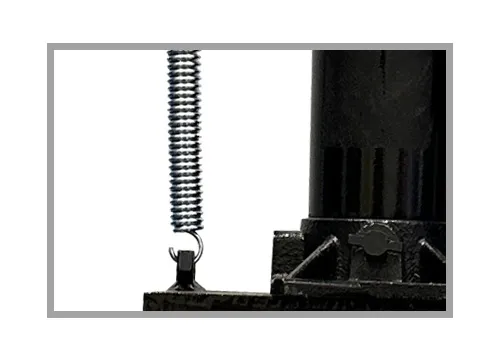

In the realm of workshop equipment, the 10t shop press stands as a beacon of efficiency and precision, a testament to the engineering prowess that characterizes modern machinery. Harnessing the power of hydraulic force, this essential tool finds its place in professional garages and home workshops alike, revered for its robust design and versatility.

From an expert perspective, selecting the right 10t shop press involves understanding the nuances of its application. Professionals advise considering the specific needs of your workshop. For instance, the type of workpieces regularly handled determines the importance of features like frame width or the ability to adjust the working table's height. Another critical factor is the press's maintenance needs; models known for their ease of hydraulic maintenance are preferred due to less downtime and reduced operational disruption. The legitimacy of a 10t shop press extends beyond its technical specifications. Renowned manufacturers often back their models with comprehensive warranties and responsive customer service, which further enhances the tool’s trustworthiness. It's advisable to check for certifications or compliance with industry standards, as these benchmarks affirm the press's credibility and safety standards. Trustworthiness in a tool also emanates from community experiences. User reviews and recommendations can provide valuable insights into the real-world performance of a 10t shop press. These narratives often highlight aspects not immediately apparent in product manuals, such as the ease of assembly, customer support quality, and unexpected durability under prolonged usage. In conclusion, the 10t shop press epitomizes the confluence of engineering excellence and practical functionality. An indispensable ally in any workshop, it brings unparalleled force and precision, streamlining processes while ensuring safety and efficiency. The key to maximizing its benefits lies in informed selection, understanding one’s specific needs, and choosing a model from a reputable manufacturer that aligns with long-term operational goals. Whether for a seasoned expert or an enthusiastic amateur, the 10t shop press represents both a challenge and a solution, a testament to the pursuit of mechanical mastery in the workshop.

From an expert perspective, selecting the right 10t shop press involves understanding the nuances of its application. Professionals advise considering the specific needs of your workshop. For instance, the type of workpieces regularly handled determines the importance of features like frame width or the ability to adjust the working table's height. Another critical factor is the press's maintenance needs; models known for their ease of hydraulic maintenance are preferred due to less downtime and reduced operational disruption. The legitimacy of a 10t shop press extends beyond its technical specifications. Renowned manufacturers often back their models with comprehensive warranties and responsive customer service, which further enhances the tool’s trustworthiness. It's advisable to check for certifications or compliance with industry standards, as these benchmarks affirm the press's credibility and safety standards. Trustworthiness in a tool also emanates from community experiences. User reviews and recommendations can provide valuable insights into the real-world performance of a 10t shop press. These narratives often highlight aspects not immediately apparent in product manuals, such as the ease of assembly, customer support quality, and unexpected durability under prolonged usage. In conclusion, the 10t shop press epitomizes the confluence of engineering excellence and practical functionality. An indispensable ally in any workshop, it brings unparalleled force and precision, streamlining processes while ensuring safety and efficiency. The key to maximizing its benefits lies in informed selection, understanding one’s specific needs, and choosing a model from a reputable manufacturer that aligns with long-term operational goals. Whether for a seasoned expert or an enthusiastic amateur, the 10t shop press represents both a challenge and a solution, a testament to the pursuit of mechanical mastery in the workshop.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025