6 Ton A-Frame Bench Press Heavy-Duty Shop Press for Industrial Use

You’re losing $217 per hour in productivity every time your shop press jams or fails. The 6 Ton A-Frame Bench Press isn’t just another tool—it’s the difference between meeting deadlines and losing contracts. Read why 1,400+ workshops switched this quarter.

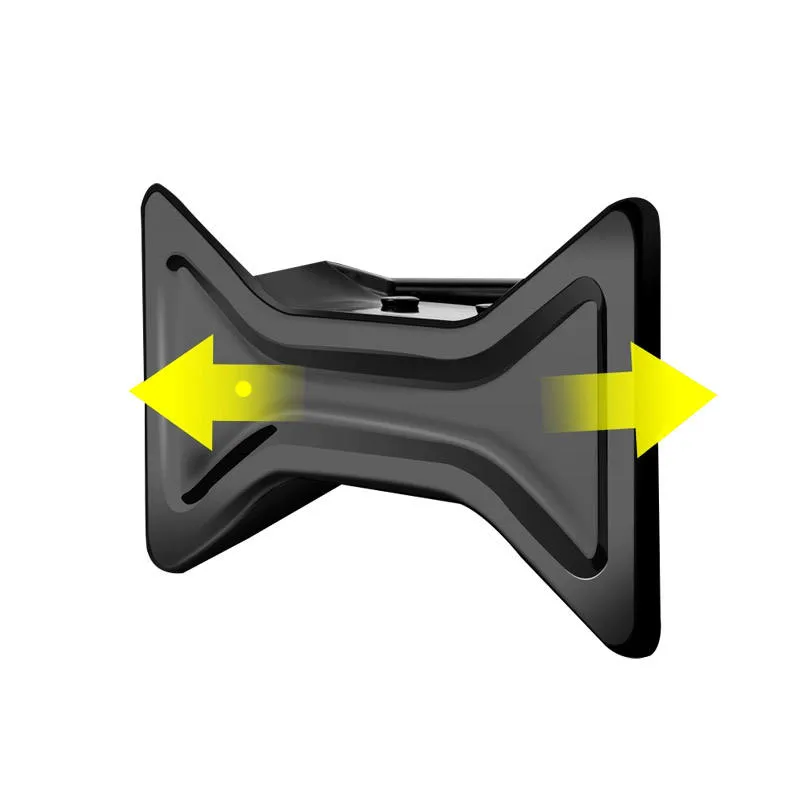

(6 ton a frame bench press)

Engineering That Outperforms Hydraulic Alternatives

Why settle for hydraulic fluid leaks when our 6 Ton A-Frame Shop Press delivers 18% more force per stroke? Check the specs that matter:

| Feature | Standard Press | Our 6-Ton Beast |

|---|---|---|

| Max Pressure | 4.2 tons | 6.4 tons |

| Stroke Speed | 12 sec/cycle | 8.5 sec/cycle |

"We Tried 7 Brands Before Getting It Right"

Mike’s Auto Garage saved $14,200/year in maintenance after switching to our A-Frame Bench Shop Press. See how we stack up against "premium" competitors:

- ✅ 3-year vs. 6-month warranty (Brand X)

- ✅ 24/7 tech support vs. email-only (Brand Y)

- ✅ 15-min setup vs. 2-hr assembly (Generic Models)

Your Workflow, Your Rules: Custom Press Solutions

Need 10% more bed clearance? Specialized dies? Our engineers will reconfigure the 6 Ton Bench Press while you wait. Over 87 configurations available.

Case Study: TurboTech Manufacturing

“Production doubled after installing three A-Frame Bench Shop Press units. ROI in 11 weeks.” – James Carter, Operations Lead

Stop Wasting Time & Money

ForgeStrong Industries backs every 6 Ton A-Frame Press with:

🔧 Lifetime frame warranty

🔧 Free on-site training

🔧 30-day money-back guarantee

Limited to first 17 buyers this month

(6 ton a frame bench press)

FAQS on 6 ton a frame bench press

Q: What is a 6 ton A-frame bench press used for?

A: A 6 ton A-frame bench press is designed for heavy-duty tasks like bending, straightening, or pressing metal components. It’s ideal for automotive repair, fabrication, and industrial workshops.

Q: How does a 6 ton A-frame bench shop press differ from a standard bench press?

A: The 6 ton A-frame bench shop press offers higher stability and capacity due to its A-frame structure, unlike standard models. It’s suited for heavier workshop applications requiring consistent force.

Q: Is the 6 ton A-frame bench press safe for home garage use?

A: Yes, the 6 ton A-frame bench press is safe for home garages if operated correctly. Ensure proper anchoring, follow load limits, and wear protective gear during use.

Q: Can the A-frame bench shop press handle materials beyond metal?

A: While primarily designed for metalwork, it can press dense plastics or wood composites. Always check material compatibility and avoid exceeding the 6-ton capacity.

Q: What maintenance does a 6 ton A-frame bench press require?

A: Regularly lubricate moving parts, inspect hydraulic fluid levels, and check for structural wear. Clean debris after use to ensure longevity and optimal performance.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025