High-Capacity Engine Support Bar-Longge|Stability&Safety

For automotive professionals and enthusiasts, the OEM Engine Support Bar represents a critical advancement in vehicle maintenance technology. Designed to provide unparalleled stability and safety during engine operations, this engine transverse bar is engineered to meet the demands of modern automotive repair. This article delves into the product's technical specifications, functional advantages, and real-world applications, while also highlighting the expertise of its manufacturer, Xianxian LONGGE Automobile Maintenance Tools Co., Ltd..

Product Overview: Engineering Precision for Engine Stability

The engine support bar is a specialized tool designed to stabilize and secure engines during maintenance, repairs, or replacements. Its primary function is to prevent unwanted movement, ensuring the engine remains in a fixed position even under high loads or dynamic conditions. This engine hoist support beam is particularly vital in scenarios where precision and safety are paramount, such as in high-speed operations or heavy-duty applications.

Key to its effectiveness is the engine balance frame, a robust structural component that minimizes vibration and shaking during use. This design not only enhances operational safety but also contributes to the longevity of the engine by reducing mechanical stress. The product's versatility is further emphasized by its compatibility with various engine types, making it an essential tool for automotive workshops and technicians.

Key Features and Functional Advantages

1. Structural Design for Stability and Durability

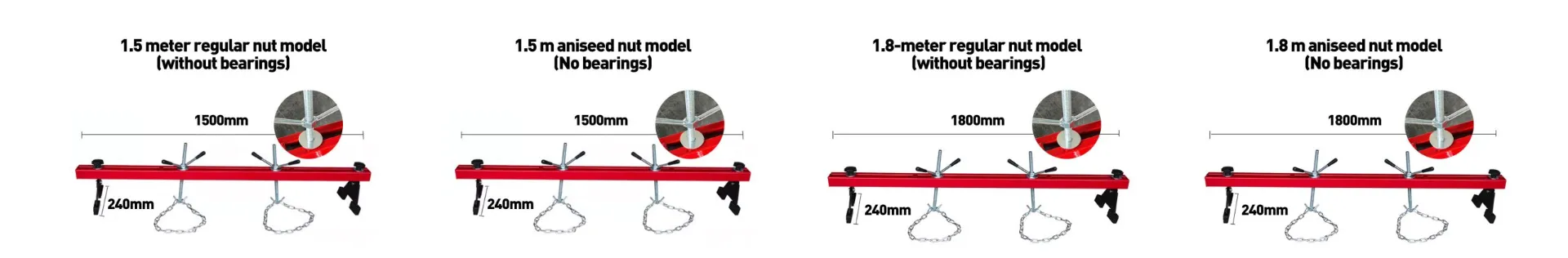

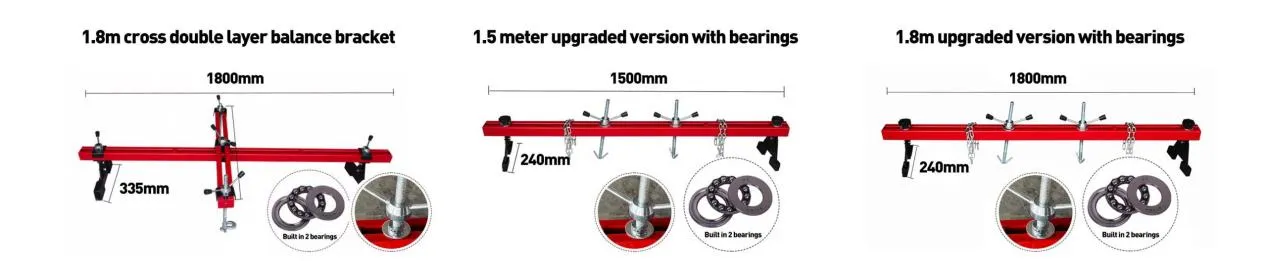

The engine support bar is constructed with a reinforced square tube framework, ensuring exceptional load-bearing capacity. The product's dimensions vary to accommodate different engine sizes, with lengths ranging from 1500mm to 1800mm. For instance, the 1500mm model features a 25×50mm square tube, while the 1800mm variant uses a 30×60mm specification. This adaptability allows users to select the most suitable configuration for their specific needs.

The material's thickness is consistently 2mm across all models, ensuring durability without compromising weight efficiency. The engine support beam is also designed with a swivel handle, enabling users to adjust the tool's position with minimal effort. This feature is particularly beneficial in tight or confined workspaces where maneuverability is crucial.

2. Non-Slip and Safety-Centric Design

To enhance user safety, the engine balance frame incorporates a rubber non-slip mat. This feature prevents the tool from shifting during operation, even when used on uneven surfaces. The non-slip texture also protects the support frame from wear and tear, extending its lifespan. Additionally, the chain design ensures that the engine remains securely fastened, reducing the risk of accidental dislodgement.

The product's design adheres to strict safety standards, as evidenced by the company's ISO, CE, and EAC certifications. These certifications underscore the manufacturer's commitment to quality and compliance with international safety protocols.

3. Enhanced Performance and User Experience

The engine support bar is engineered to optimize engine performance by minimizing vibrations. According to NIST (National Institute of Standards and Technology), reducing mechanical vibrations is critical for improving the efficiency and longevity of automotive components. By stabilizing the engine, this tool helps reduce fuel consumption, wear, and tear, ultimately extending the engine's operational life.

Furthermore, the engine balance frame significantly reduces noise and vibration in vehicles. This not only enhances driver and passenger comfort but also aligns with modern automotive design principles that prioritize noise reduction. The product's ability to prevent engine movement during emergencies, such as sudden braking or collisions, further enhances vehicle safety, as highlighted by NIST's research on automotive safety standards.

Technical Specifications: A Comprehensive Overview

| Parameter | 1500mm Model | 1800mm Model |

|---|---|---|

| Length | 1500mm | 1800mm |

| Square Tube Specification | 25×50mm | 25×50mm |

| Package Size | 153×17×9cm | 183×17×9cm |

| Gross Weight | 13kg | 22kg |

| Net Weight | 12kg | 21kg |

| Steel Thickness | 2mm | 2mm |

The engine support bar is available in multiple configurations to suit diverse requirements. For example, the 1500mm model with a 25×50mm square tube is ideal for compact engines, while the 1800mm variant with a 30×60mm specification is better suited for larger, heavy-duty engines. The product's weight range, from 12kg to 22kg, ensures that users can choose a model that balances portability and robustness.

Applications: Versatile Use in Automotive Maintenance

The engine support bar is a versatile tool with applications spanning various automotive scenarios. Its primary use is in engine hoisting, where it provides a stable platform for lifting and securing engines during repairs. This is particularly useful in scenarios involving engine replacements, where precision and safety are critical.

Additionally, the product is employed in vehicle inspection and component maintenance. By stabilizing the engine, it allows technicians to access hard-to-reach areas with ease, facilitating thorough inspections and repairs. The engine balance frame also plays a role in crash testing and emergency scenarios, where it prevents engine displacement and enhances vehicle safety.

For automotive workshops, the engine support bar is an essential investment. Its ability to reduce downtime and improve operational efficiency makes it a valuable asset in any professional setting. The product's durability and ease of use further justify its inclusion in routine maintenance protocols.

Company Background: Xianxian LONGGE Automobile Maintenance Tools Co., Ltd.

Manufactured by Xianxian LONGGE Automobile Maintenance Tools Co., Ltd., the engine support bar is a testament to the company's expertise in automotive tool development. Based in Xianxian County, the company has established itself as a leading producer of high-quality maintenance equipment, with products exported to numerous countries worldwide.

With a professional production team and a focus on innovation, Xianxian LONGGE ensures that its tools meet the highest standards of quality and reliability. The company's products are certified under ISO, CE, and EAC standards, reflecting its commitment to international safety and quality benchmarks. This dedication to excellence has earned the company a reputation for delivering tools that meet the rigorous demands of the automotive industry.

Conclusion: A Reliable Solution for Automotive Professionals

The OEM Engine Support Bar is a critical tool for automotive maintenance, offering unmatched stability, safety, and versatility. Its advanced design, combined with high-quality materials and rigorous certifications, ensures that it meets the demands of modern automotive repair. Whether used for engine hoisting, inspection, or emergency scenarios, this engine support beam is an indispensable asset for professionals and enthusiasts alike.

For those seeking reliable automotive tools, Xianxian LONGGE Automobile Maintenance Tools Co., Ltd. provides a trusted solution. With a commitment to innovation and quality, the company continues to set benchmarks in the industry. Contact them today to explore their range of products and discover how they can enhance your automotive maintenance operations.

References

NIST (National Institute of Standards and Technology). (n.d.). https://www.nist.gov. Retrieved from https://www.nist.gov.

For further information on automotive safety standards and vibration reduction technologies, refer to NIST's research on automotive engineering and measurement standards.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025