Welcome to our online store!

Feb . 20, 2025 10:09

Back To List

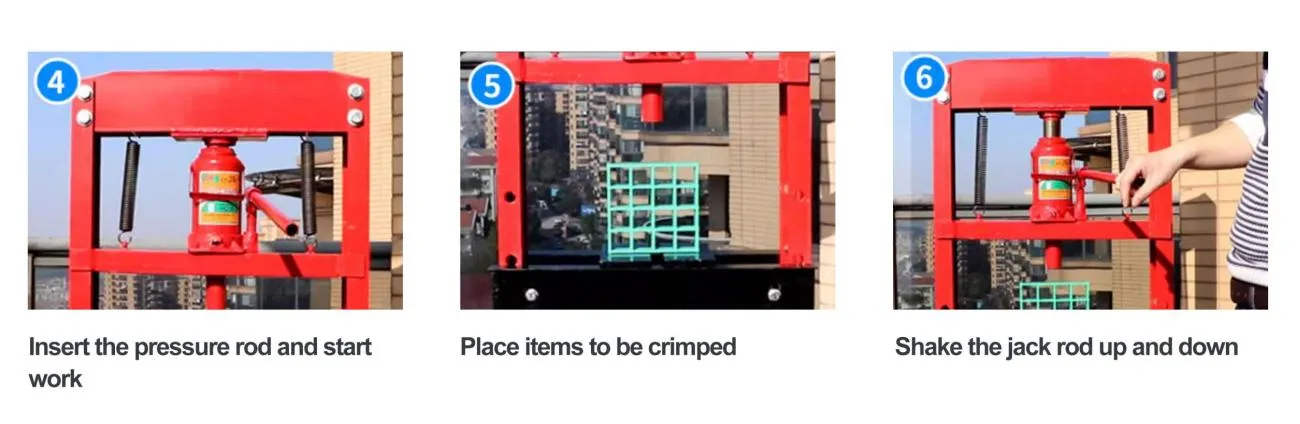

Manual Press Hand Type 6tons Hydraulic Shop Press H Frame Hydraulic Press

Unlocking the Potential of Hydraulic Floor Press A New Era in Mechanical Operations

From an experiential standpoint, working with hydraulic floor presses can transform operational dynamics. Consider the ongoing innovations that are incorporating IoT technology with these machines. This convergence allows for real-time monitoring and diagnostics, providing invaluable insights into performance metrics and preemptive maintenance alerts. Such capabilities not only extend the lifespan of the machinery but also optimize output by minimizing unplanned downtimes. Furthermore, the compact design of many hydraulic floor presses maximizes floor space efficiency, a crucial advantage in crowded workshops. Despite their formidable power, these machines are ingeniously designed to be space-conscious, an attribute that augments their usability for small and large enterprises alike, thereby broadening their application horizon. As industries advance towards leaner operations with a focus on sustainability, hydraulic floor presses present a compelling model for energy efficiency. The inherent nature of hydraulic systems to recycle operational fluids aligns with environmental strategies, reducing waste and enhancing the sustainability quotient of manufacturing processes. Environmental stewardship is further evident in new models equipped with low-energy consumption technologies, affirming these presses as pioneers in adopting green initiatives. The legacy of hydraulic floor presses is not only built upon their technical prowess but also through the narratives of countless experts who have tested the bounds of their utility. Their constant evolution reflects an ongoing commitment to meet and exceed industrial demands while maintaining unparalleled performance metrics. This enduring legacy bolsters their stance as authoritative figures within the mechanical equipment domain. In conclusion, hydraulic floor presses epitomize the synthesis of engineering innovation, expert operation, and authoritative reliability. Their cost-effectiveness, operational excellence, and adaptability render them invaluable assets in diverse industrial landscapes. For any enterprise aiming to enhance their production capabilities while adhering to stringent quality standards, investing in a hydraulic floor press is not just a choice but a strategic imperative. Affording users precision, durability, and versatility, these machines affirm their status as quintessential components in the modern industrial toolkit.

From an experiential standpoint, working with hydraulic floor presses can transform operational dynamics. Consider the ongoing innovations that are incorporating IoT technology with these machines. This convergence allows for real-time monitoring and diagnostics, providing invaluable insights into performance metrics and preemptive maintenance alerts. Such capabilities not only extend the lifespan of the machinery but also optimize output by minimizing unplanned downtimes. Furthermore, the compact design of many hydraulic floor presses maximizes floor space efficiency, a crucial advantage in crowded workshops. Despite their formidable power, these machines are ingeniously designed to be space-conscious, an attribute that augments their usability for small and large enterprises alike, thereby broadening their application horizon. As industries advance towards leaner operations with a focus on sustainability, hydraulic floor presses present a compelling model for energy efficiency. The inherent nature of hydraulic systems to recycle operational fluids aligns with environmental strategies, reducing waste and enhancing the sustainability quotient of manufacturing processes. Environmental stewardship is further evident in new models equipped with low-energy consumption technologies, affirming these presses as pioneers in adopting green initiatives. The legacy of hydraulic floor presses is not only built upon their technical prowess but also through the narratives of countless experts who have tested the bounds of their utility. Their constant evolution reflects an ongoing commitment to meet and exceed industrial demands while maintaining unparalleled performance metrics. This enduring legacy bolsters their stance as authoritative figures within the mechanical equipment domain. In conclusion, hydraulic floor presses epitomize the synthesis of engineering innovation, expert operation, and authoritative reliability. Their cost-effectiveness, operational excellence, and adaptability render them invaluable assets in diverse industrial landscapes. For any enterprise aiming to enhance their production capabilities while adhering to stringent quality standards, investing in a hydraulic floor press is not just a choice but a strategic imperative. Affording users precision, durability, and versatility, these machines affirm their status as quintessential components in the modern industrial toolkit.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025