Welcome to our online store!

Feb . 18, 2025 11:46

Back To List

2 Ton Folding Shop Crane Lifting Machine Mini Truck Hydraulic Jack Engine Crane Folding Crane

For mechanical workshops and DIY enthusiasts, the hydraulic shop press has become an indispensable tool, especially the 12-ton variety, which strikes a perfect balance between capacity and usability. Its applications span from bending metal to pressing bearings, making it a versatile choice for many tasks.

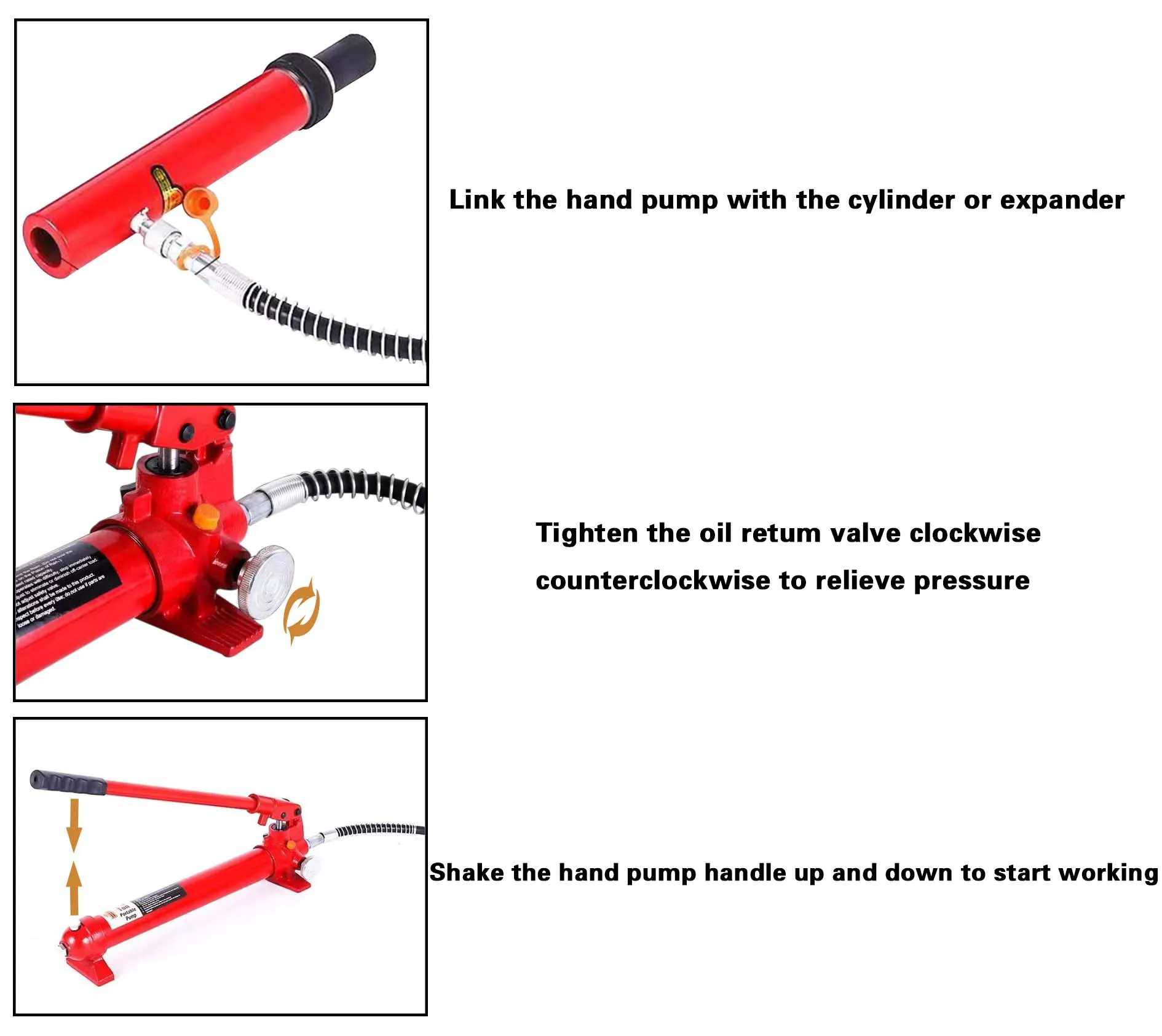

Safety being paramount, operators must adhere to established guidelines. Following the user manual for setup and operation reduces the risk of accidents. It's vital to ensure the workpiece is securely positioned and correctly aligned before applying pressure. Additionally, protective eyewear and gloves should be worn to guard against potential hazards such as flying debris or sudden component failure. Building trust with a hydraulic shop press is essential for long-term satisfaction and efficiency. Regular training and staying updated on best practices contribute to an authoritative understanding of the tool, leading to more effective usage. Workshops investing in quality 12-ton presses often find that their ability to handle diverse workloads with precision translates to higher client satisfaction and repeat business. Furthermore, the trustworthiness of a product like the 12-ton hydraulic shop press is often reflected in its manufacturer’s reputation. Reputable brands provide warranties, detailed user manuals, and responsive customer support, which are all indicators of a trustworthy investment. Choosing a well-known brand not only secures reliable performance but also offers peace of mind, knowing that support is available when needed. In conclusion, a 12-ton hydraulic shop press is not just a piece of equipment; it's a cornerstone of mechanical efficiency and precision in workshops. By understanding its detailed operation, ensuring regular maintenance, and observing safety protocols, users can maximize the benefits this tool offers. For those in automotive, metalworking, or small-scale manufacturing, investing in a high-quality 12-ton press is a decision that promises significant returns in terms of productivity and reliability.

Safety being paramount, operators must adhere to established guidelines. Following the user manual for setup and operation reduces the risk of accidents. It's vital to ensure the workpiece is securely positioned and correctly aligned before applying pressure. Additionally, protective eyewear and gloves should be worn to guard against potential hazards such as flying debris or sudden component failure. Building trust with a hydraulic shop press is essential for long-term satisfaction and efficiency. Regular training and staying updated on best practices contribute to an authoritative understanding of the tool, leading to more effective usage. Workshops investing in quality 12-ton presses often find that their ability to handle diverse workloads with precision translates to higher client satisfaction and repeat business. Furthermore, the trustworthiness of a product like the 12-ton hydraulic shop press is often reflected in its manufacturer’s reputation. Reputable brands provide warranties, detailed user manuals, and responsive customer support, which are all indicators of a trustworthy investment. Choosing a well-known brand not only secures reliable performance but also offers peace of mind, knowing that support is available when needed. In conclusion, a 12-ton hydraulic shop press is not just a piece of equipment; it's a cornerstone of mechanical efficiency and precision in workshops. By understanding its detailed operation, ensuring regular maintenance, and observing safety protocols, users can maximize the benefits this tool offers. For those in automotive, metalworking, or small-scale manufacturing, investing in a high-quality 12-ton press is a decision that promises significant returns in terms of productivity and reliability.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025