OEM Engine Support Bar - Xianxian Longge | Stability, Safety, Durability

When it comes to automotive maintenance, the engine support bar plays a critical role in ensuring the safety, stability, and efficiency of engine-related tasks. This article delves into the technical specifications, features, and applications of the OEM Engine Support Bar, highlighting its value for mechanics, automotive professionals, and vehicle enthusiasts. Additionally, we explore the background of the manufacturer, Xianxian County Longge Automobile Maintenance Tools Co., Ltd., and reference authoritative sources such as the National Institute of Standards and Technology (NIST) to underscore the importance of precision and reliability in automotive tools.

Understanding the OEM Engine Support Bar

The OEM Engine Support Bar is a specialized tool designed to stabilize and support engines during maintenance, repair, or replacement. Its primary function is to reduce engine vibration and shaking, ensuring smooth operation even under high-speed or high-load conditions. This stability is crucial for preventing mechanical failures and enhancing the overall performance of the vehicle.

Key Features and Design

One of the standout features of the OEM Engine Support Bar is its swivel handle, which allows for easy maneuverability and saves time and effort during use. The adjustable solid structure ensures strong stability, making it suitable for a wide range of engine sizes and configurations. Additionally, the inclusion of a rubber non-slip mat prevents the tool from slipping, protecting both the support frame and the engine surface. The chain design further enhances durability, as it is made from high-quality materials that resist breakage during use.

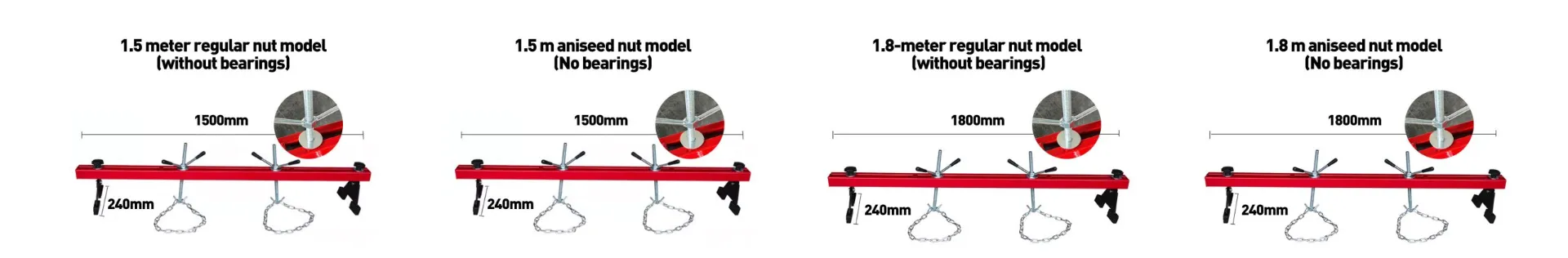

Figure 1: Structural design of the OEM Engine Support Bar, emphasizing its stability and durability.

Technical Specifications

The OEM Engine Support Bar is available in multiple configurations, each tailored to specific requirements. Below is a detailed technical specification table for the product:

| Parameter | 1500mm (25x50mm) | 1500mm (30x60mm) | 1800mm (25x50mm) | 1800mm (30x60mm) |

|---|---|---|---|---|

| Length | 1500mm | 1500mm | 1800mm | 1800mm |

| Square Tube Specification | 25x50mm | 30x60mm | 25x50mm | 30x60mm |

| Package Size | 153x17x9cm | 153x17x9cm | 183x17x9cm | 183x17x9cm |

| Gross Weight | 13kg | 15.5kg | 14.5kg | 17kg |

| Net Weight | 12kg | 14.5kg | 13.5kg | 16kg |

| Steel Thickness | 2mm | 2mm | 2mm | 2mm |

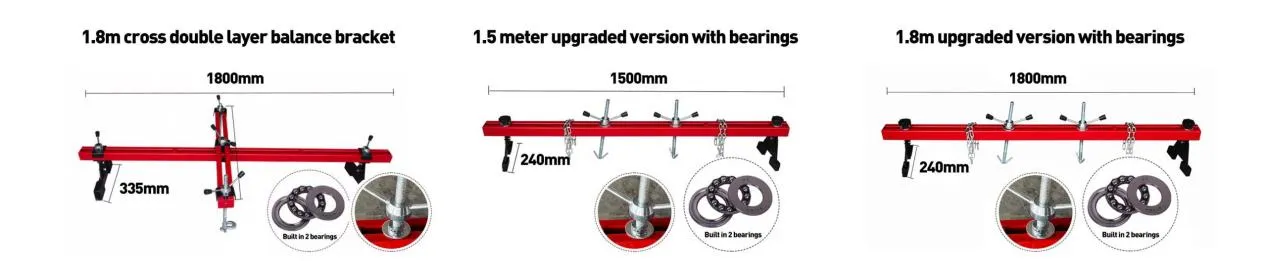

For additional configurations, the following table provides details for the 1800mm and 1500mm models:

| Parameter | 1800mm (25x50mm) | 1500mm (25x50mm) | 1800mm (25x50mm) |

|---|---|---|---|

| Length | 1800mm | 1500mm | 1800mm |

| Square Tube Specification | 25x50mm | 25x50mm | 25x50mm |

| Package Size | 183x17x9cm | 153x17x9cm | 183x17x9cm |

| Gross Weight | 22kg | 13.5kg | 15kg |

| Net Weight | 21kg | 12.5kg | 14kg |

| Steel Thickness | 2mm | 2mm | 2mm |

Figure 2: Technical specifications of the OEM Engine Support Bar, highlighting its versatility and robustness.

Applications and Benefits

The OEM Engine Support Bar is designed for a wide range of applications, particularly in the automotive industry. Its primary use cases include:

- Engine Maintenance: The tool provides a stable platform for engine removal, installation, and inspection, reducing the risk of damage to the engine and surrounding components.

- Vehicle Repair: It is ideal for tasks such as replacing engine mounts, aligning the engine, or performing diagnostic checks.

- Industrial Use: The robust construction of the support bar makes it suitable for heavy-duty applications in automotive workshops and manufacturing facilities.

One of the key benefits of the OEM Engine Support Bar is its ability to optimize engine performance by minimizing vibration. According to research by the National Institute of Standards and Technology (NIST), reducing mechanical vibrations can significantly improve the efficiency and longevity of engine systems [1]. This aligns with the design philosophy of the OEM Engine Support Bar, which prioritizes precision and reliability.

Figure 3: Practical applications of the OEM Engine Support Bar in automotive workshops.

Enhanced Safety and User Experience

The OEM Engine Support Bar is engineered with safety in mind. Its non-slip mat and durable chain design ensure that the tool remains secure during use, even in high-stress scenarios. This is particularly important in emergency situations, such as a crash or sudden braking, where the engine may experience unexpected movement. The support bar acts as a critical safety feature, preventing potential hazards and protecting both the vehicle and its occupants.

Furthermore, the tool's adjustable structure allows for easy customization, making it accessible to users of varying skill levels. This adaptability ensures that the OEM Engine Support Bar can be utilized in diverse environments, from small garage setups to large-scale automotive manufacturing plants.

Figure 4: Packaging and design of the OEM Engine Support Bar, emphasizing its user-friendly features.

Company Background: Xianxian County Longge Automobile Maintenance Tools Co., Ltd.

The OEM Engine Support Bar is manufactured by Xianxian County Longge Automobile Maintenance Tools Co., Ltd., a reputable company with extensive experience in producing high-quality automotive tools. The company has a professional production team and has successfully obtained certifications such as ISO, CE, and EAC, ensuring compliance with international standards. These certifications underscore the company's commitment to quality and safety, making its products a trusted choice for automotive professionals worldwide.

With a focus on innovation and customer satisfaction, Xianxian County Longge has established a strong presence in the global market. The company's products are exported to numerous countries, reflecting its reputation for reliability and performance. For those interested in the OEM Engine Support Bar or other automotive tools, the company offers competitive pricing, free quotes, and tailored procurement solutions to meet specific needs.

Conclusion

The OEM Engine Support Bar is a vital tool for ensuring the safety, stability, and efficiency of engine-related tasks in the automotive industry. Its advanced design, robust specifications, and user-friendly features make it an indispensable asset for mechanics and automotive professionals. By incorporating the principles of precision and reliability, the product aligns with the standards set by organizations like NIST, which emphasize the importance of accurate measurements and quality control in manufacturing [1]. As the automotive industry continues to evolve, tools like the OEM Engine Support Bar will remain essential in driving innovation and improving vehicle performance.

References

[1] National Institute of Standards and Technology (NIST). https://www.nist.gov

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025