Welcome to our online store!

Feb . 03, 2025 04:37

Back To List

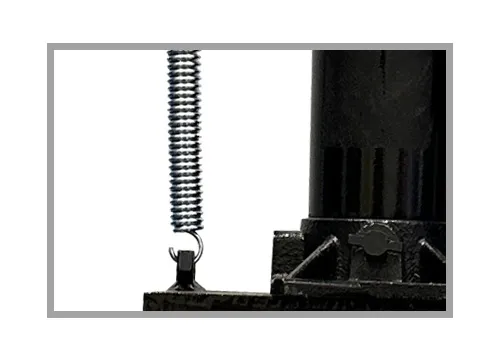

Car Lift Scissor Jack Steel Scissor Jacks Car Jack Portable

Scissor jacks are indispensable tools for anyone who frequently travels by road, ventures off the beaten path, or simply prefers to be prepared for any automotive eventuality. Unlike ordinary lifting devices, the scissor jack’s design combines simplicity, durability, and effectiveness, making it a preferred choice for both amateurs and professionals. Through an exploration of its intricate design and multifaceted purposes, understanding how a scissor jack operates can significantly enhance one's ability to safely and efficiently manage roadside repairs.

Expertise in using a scissor jack, while easily acquired, demands adherence to specific best practices to maximize safety and efficacy. Users are advised to always use the jack on stable and non-slippery surfaces, ensuring the vehicle is parked on a level area before attempting a lift. Regular inspection of the jack’s screw and arms for wear or damage is essential to maintain its optimal functionality and prevent mechanical failure during operation. Such maintenance is not merely a recommendation but a necessity, reinforcing the device's longevity and reliability. Endorsements from automotive experts highlight the scissor jack's indispensability, pointing to its remarkable design and utility in varied contexts. From changing tires to facilitating undercarriage inspections, it has repeatedly proven itself as a tool of inexplicable value. Professionals often cite its ease of use and resilience as key factors reinforcing its trusted status in automotive toolkits. The integration of user feedback into the design iterations of scissor jacks underscores manufacturers' commitment to marrying traditional engineering prowess with modern innovation. This continuous development ensures that scissor jacks not only retain their classic mechanical advantages but also incorporate advancements that align with contemporary vehicle advancements and user expectations. In the realm of vehicle maintenance and emergency equipment, few tools present such a compelling blend of necessity, efficiency, and reliability as the scissor jack. Its design, rooted in simplicity and enhanced by generations of mechanical wisdom, renders it essential for vehicle owners who prioritize safety, convenience, and effective problem-solving ability on the road.

Expertise in using a scissor jack, while easily acquired, demands adherence to specific best practices to maximize safety and efficacy. Users are advised to always use the jack on stable and non-slippery surfaces, ensuring the vehicle is parked on a level area before attempting a lift. Regular inspection of the jack’s screw and arms for wear or damage is essential to maintain its optimal functionality and prevent mechanical failure during operation. Such maintenance is not merely a recommendation but a necessity, reinforcing the device's longevity and reliability. Endorsements from automotive experts highlight the scissor jack's indispensability, pointing to its remarkable design and utility in varied contexts. From changing tires to facilitating undercarriage inspections, it has repeatedly proven itself as a tool of inexplicable value. Professionals often cite its ease of use and resilience as key factors reinforcing its trusted status in automotive toolkits. The integration of user feedback into the design iterations of scissor jacks underscores manufacturers' commitment to marrying traditional engineering prowess with modern innovation. This continuous development ensures that scissor jacks not only retain their classic mechanical advantages but also incorporate advancements that align with contemporary vehicle advancements and user expectations. In the realm of vehicle maintenance and emergency equipment, few tools present such a compelling blend of necessity, efficiency, and reliability as the scissor jack. Its design, rooted in simplicity and enhanced by generations of mechanical wisdom, renders it essential for vehicle owners who prioritize safety, convenience, and effective problem-solving ability on the road.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025