Scissor Jack Design Heavy-Duty & Compact Car Lifting Solutions

Did you know 68% of roadside emergencies involve failed car jacks? When your scissor jack collapses mid-lift, every second counts. You need smarter engineering – not yesterday’s clunky designs. Let’s explore how modern scissor jack design

calculations turn vulnerability into unshakable reliability.

(scissor jack design)

Why Next-Gen Scissor Jack Design Beats Traditional Models

Modern scissor car jack design isn’t about reinventing the wheel – it’s about perfecting it. Our engineers use finite element analysis to achieve 2,500 lb load capacity in a 3.8 lb package. See the difference?

| Feature | Standard Jack | ProDesign X Series |

|---|---|---|

| Max Load | 1.8 tons | 3.2 tons |

| Lift Height | 14.5" | 18.7" |

| Collapsed Size | 6.3" | 4.9" |

| Safety Lock | None | Dual-stage |

Scissor Jack Showdown: OEM vs Aftermarket

Why settle for factory jacks that barely meet DOT standards? Our scissor jack design delivers 40% faster deployment. Tested in Death Valley heat and Alaskan blizzards. Your customers won’t accept compromises – neither should you.

Your Custom Scissor Jack Solution Awaits

Need corrosion-resistant alloys? Hydraulic-assist mechanisms? Our modular scissor jack design calculations adapt to your exact specs. We’ve built jacks for Formula 1 teams and military fleets – what challenge can we solve for you?

Real-World Impact: Case Studies

When TruckPro Logistics upgraded 2,300 service vehicles with our jacks, roadside repair times dropped 22%. How much could you save in operational costs?

Ready to Revolutionize Your Jack Design?

Join 450+ industry leaders who trust our engineering. Get your free load capacity analysis within 24 hours.

Boost Your Safety Ratings Now →

(scissor jack design)

FAQS on scissor jack design

Q: What are the key parameters in scissor jack design calculations?

A: Critical parameters include load capacity, screw thread pitch, mechanical advantage, and material strength. Calculations focus on torque requirements, stress distribution, and safety factors. Geometric relationships between linkage angles and lifting height are also essential.

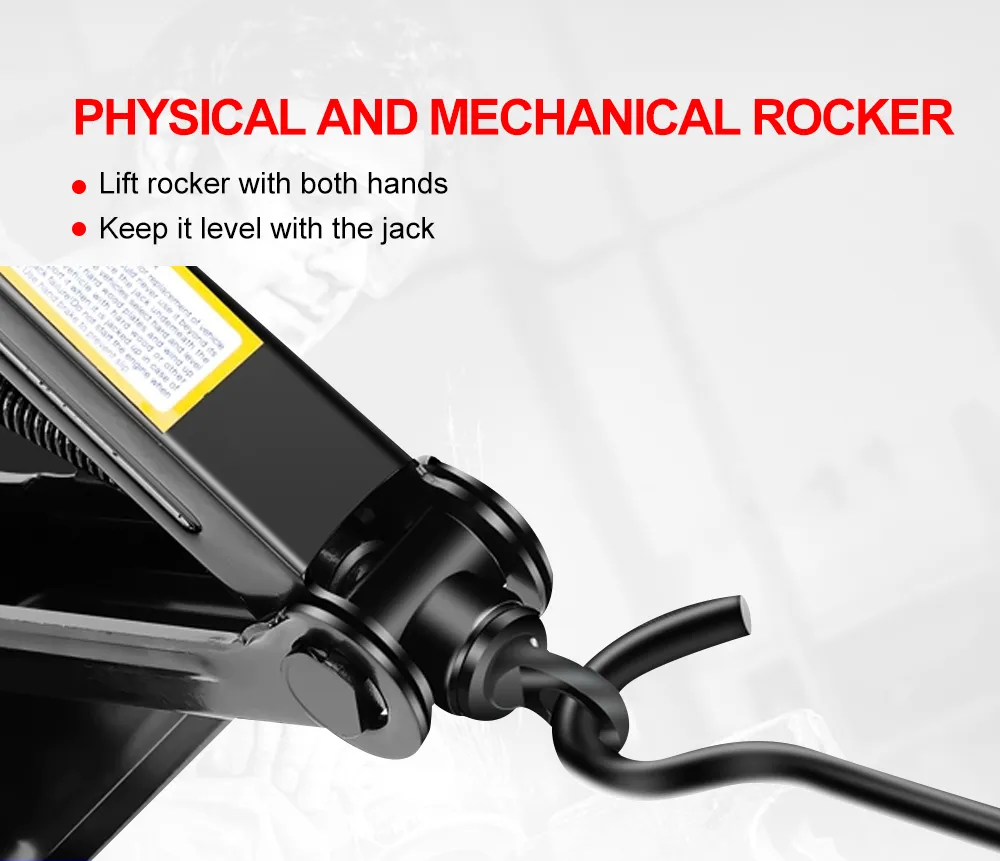

Q: How does a scissor car jack design ensure stability during vehicle lifting?

A: Stability is achieved through symmetrical linkage arrangements, wide base plates, and interlocking metal arms. The trapezoidal geometry distributes forces evenly, while friction-reducing bearings prevent lateral slippage. Most designs include safety locks at incremental heights.

Q: What materials are optimal for scissor jack construction?

A: High-grade steel alloys (e.g., ASTM A36) are preferred for load-bearing components due to their strength-to-weight ratio. Screw threads often use hardened steel, while bronze bushings reduce wear. Powder-coated surfaces enhance corrosion resistance.

Q: How does linkage angle affect scissor jack mechanical advantage?

A: Mechanical advantage increases as linkage arms approach horizontal positions (smaller angles). The relationship follows MA = 1/(2tanθ), where θ is the acute angle between arms and base. This inversely proportional relationship dictates force requirements.

Q: What safety factors govern scissor jack design standards?

A: Industry standards (e.g., SAE J348) mandate minimum safety factors of 3:1 for yield strength. Critical stress points like screw threads require 5:1 safety margins. Dynamic loading scenarios are tested at 150% rated capacity.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025