Welcome to our online store!

2 月 . 16, 2025 12:56

Back To List

sheetrock panel hoist

The efficiency and safety of working with drywall have been significantly enhanced by innovations like the sheetrock panel hoist. Let's delve into a real-world examination of why this tool is indispensable for both professionals and enthusiastic DIYers, solidifying its spot as an expert-recommended device in drywall installation.

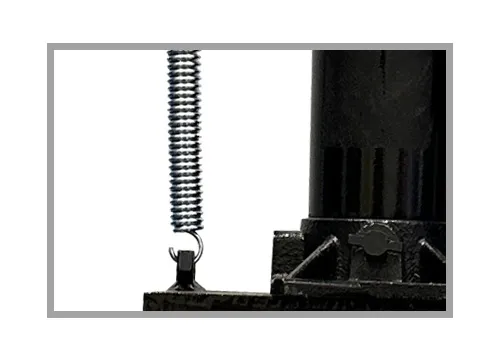

Regarding its trustworthiness and dependability, user experiences commonly highlight this tool's robust construction and longevity. Typically made from welded steel, a sheetrock panel hoist is built to withstand the rigors and demands of various construction environments. In practice, this durability translates into long-term cost savings for users, as the likelihood of breakdowns and malfunctions is significantly minimized. Furthermore, many hoist designs come equipped with safety locks and cradles, features that serve to secure panels during lifting and installation, thereby minimizing the risk of accidents or damage. Real-world expertise underscores that operating a sheetrock panel hoist requires minimal learning and adaptation time. Users, regardless of prior experience, quickly become adept at utilizing the tool to its full capacity. This ease of operation is a substantial advantage in fast-paced environments where efficiency is paramount. The tool’s simplicity does not compromise its functionality; instead, it enhances the user’s proficiency in drywall installation, allowing professionals to complete jobs with increased accuracy and in less time. In terms of authority, many construction experts and seasoned builders advocate for the use of sheetrock panel hoists as an industry standard. This advocacy comes backed by years of reliable service and successful projects, reinforcing the notion that investing in a high-quality panel hoist is an investment in the craftsmanship of the final product. Testimonials from longtime users often report a notable increase in job site safety and project turnarounds. In conclusion, the sheetrock panel hoist stands as a paradigm of technological advancement in construction tools. Its introduction into a project workflow not only optimizes processes but assures elevated standards of safety, precision, and reliability. For anyone committed to delivering top-tier quality in drywall installations, the implementation of a sheetrock panel hoist is a carefully evaluated decision backed by industry experience, authoritative endorsements, and a proven track record of trustworthiness.

Regarding its trustworthiness and dependability, user experiences commonly highlight this tool's robust construction and longevity. Typically made from welded steel, a sheetrock panel hoist is built to withstand the rigors and demands of various construction environments. In practice, this durability translates into long-term cost savings for users, as the likelihood of breakdowns and malfunctions is significantly minimized. Furthermore, many hoist designs come equipped with safety locks and cradles, features that serve to secure panels during lifting and installation, thereby minimizing the risk of accidents or damage. Real-world expertise underscores that operating a sheetrock panel hoist requires minimal learning and adaptation time. Users, regardless of prior experience, quickly become adept at utilizing the tool to its full capacity. This ease of operation is a substantial advantage in fast-paced environments where efficiency is paramount. The tool’s simplicity does not compromise its functionality; instead, it enhances the user’s proficiency in drywall installation, allowing professionals to complete jobs with increased accuracy and in less time. In terms of authority, many construction experts and seasoned builders advocate for the use of sheetrock panel hoists as an industry standard. This advocacy comes backed by years of reliable service and successful projects, reinforcing the notion that investing in a high-quality panel hoist is an investment in the craftsmanship of the final product. Testimonials from longtime users often report a notable increase in job site safety and project turnarounds. In conclusion, the sheetrock panel hoist stands as a paradigm of technological advancement in construction tools. Its introduction into a project workflow not only optimizes processes but assures elevated standards of safety, precision, and reliability. For anyone committed to delivering top-tier quality in drywall installations, the implementation of a sheetrock panel hoist is a carefully evaluated decision backed by industry experience, authoritative endorsements, and a proven track record of trustworthiness.

Prev:

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025