Welcome to our online store!

فوریه . 18, 2025 12:04

Back To List

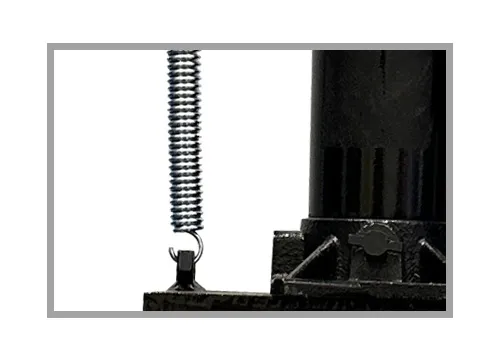

Manual Press Hand Type 6tons Hydraulic Shop Press H Frame Hydraulic Press

The hydraulic shop press, particularly the 20-ton variant, stands out as a pivotal tool in both professional workshops and home garages. Its robust construction and immense pressing power make it indispensable for an array of tasks, from bending metals to pressing bearings. But what makes this tool truly remarkable? Let's dive into its intricacies, shedding light on why the 20-ton hydraulic shop press is endorsed by both novices and seasoned professionals alike.

Safety, however, is the cornerstone of the hydraulic shop press's design. Equipped with features such as overload protection valves and firm anchoring provisions, it minimizes the risk of accidents. In environments demanding stringent safety standards, such as industrial workshops, the 20-ton press stands tall, ensuring both operator safety and task efficacy. For hobbyists working from home, understanding and adhering to operational guidelines ensures a secure and hazard-free environment. In terms of expertise, using a 20-ton hydraulic shop press demands a sound understanding of its mechanics. It is not merely about exerting force but understanding the nuances of pressure levels and their applications. Training and practical exposure empower users to unlock its full potential, transforming novices into experts. This expertise is further supported by comprehensive user manuals, offering in-depth insights into operation, maintenance, and troubleshooting. The authority of the 20-ton hydraulic shop press in the market is further reaffirmed by the credibility of its manufacturers. Established brands with a track record of delivering quality and reliability offer these tools with extensive warranties, ensuring trust and peace of mind. Reviews from industry experts and user testimonials amalgamate to illustrate its supremacy, addressing common concerns while providing solutions that reinforce its market dominance. Conclusively, the 20-ton hydraulic shop press is more than just a formidable tool; it's an investment in quality, efficiency, and safety. Its indispensability in tasks requiring precision, coupled with the manufacturer's commitment to quality, makes it a tool worth its weight in gold. Whether you're an automotive technician or a metal fabricator, understanding and leveraging the power of a hydraulic shop press can elevate your craft, underscoring reliability and expertise in your services. As such, when considering an addition to your toolkit, the 20-ton hydraulic shop press is a choice that aligns with innovation, authority, and trust.

Safety, however, is the cornerstone of the hydraulic shop press's design. Equipped with features such as overload protection valves and firm anchoring provisions, it minimizes the risk of accidents. In environments demanding stringent safety standards, such as industrial workshops, the 20-ton press stands tall, ensuring both operator safety and task efficacy. For hobbyists working from home, understanding and adhering to operational guidelines ensures a secure and hazard-free environment. In terms of expertise, using a 20-ton hydraulic shop press demands a sound understanding of its mechanics. It is not merely about exerting force but understanding the nuances of pressure levels and their applications. Training and practical exposure empower users to unlock its full potential, transforming novices into experts. This expertise is further supported by comprehensive user manuals, offering in-depth insights into operation, maintenance, and troubleshooting. The authority of the 20-ton hydraulic shop press in the market is further reaffirmed by the credibility of its manufacturers. Established brands with a track record of delivering quality and reliability offer these tools with extensive warranties, ensuring trust and peace of mind. Reviews from industry experts and user testimonials amalgamate to illustrate its supremacy, addressing common concerns while providing solutions that reinforce its market dominance. Conclusively, the 20-ton hydraulic shop press is more than just a formidable tool; it's an investment in quality, efficiency, and safety. Its indispensability in tasks requiring precision, coupled with the manufacturer's commitment to quality, makes it a tool worth its weight in gold. Whether you're an automotive technician or a metal fabricator, understanding and leveraging the power of a hydraulic shop press can elevate your craft, underscoring reliability and expertise in your services. As such, when considering an addition to your toolkit, the 20-ton hydraulic shop press is a choice that aligns with innovation, authority, and trust.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025