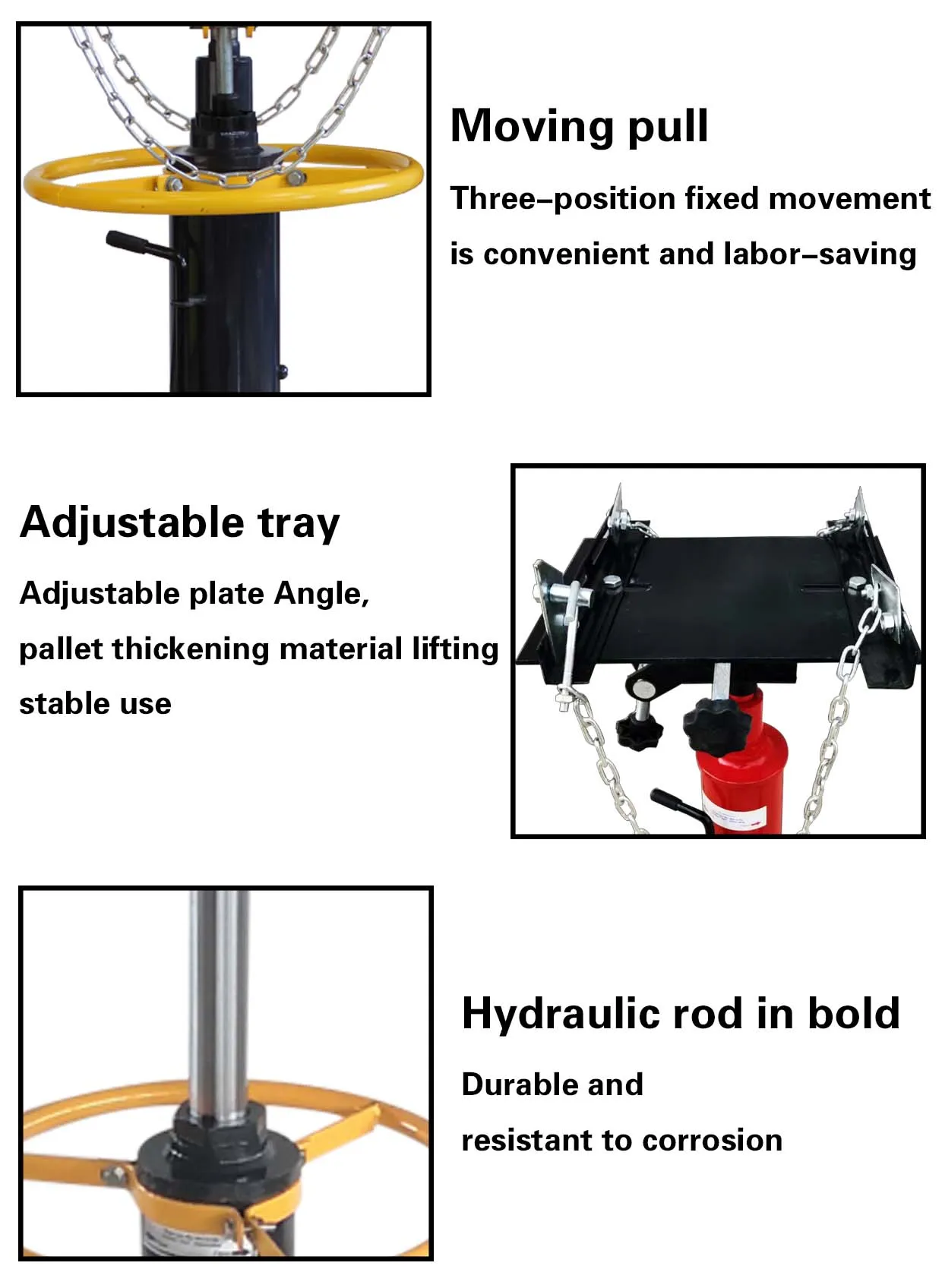

Small, flexible and easy to operate 2 ton horizontal jack small car jacks small hydraulic floor jacks for sale

Furthermore, incorrect usage is a key factor contributing to floor jack failures. Overloading is a typical mistake. Each jack has a rated capacity, and exceeding it not only compromises the jack’s effectiveness but also poses safety risks. Always adhere to the manufacturer's specified weight limits and use jack stands for added security when working beneath a vehicle. Climate and environment can also affect jack performance. Extreme temperatures can cause hydraulic fluid to thicken or thin, affecting the jack’s ability to lift. In colder climates, consider storing your jack in a temperature-controlled area or using a fluid rated for low temperatures to maintain optimal performance. Preventive maintenance is vital in extending the life and efficiency of your floor jack. Regular cleaning, lubrication of moving parts, and storage in a dry, safe environment can prevent many common issues. Developing a maintenance schedule based on manufacturer guidelines enhances both performance and safety. In conclusion, understanding the intricacies of floor jack operation can preempt many issues related to lifting failure. By combining practical experience with professional advice, users can ensure their equipment runs smoothly and safely. Routine inspection, proper usage, and diligent care are integral to optimizing performance. Remember to always follow the manufacturer's instructions and seek professional assistance when necessary to maintain the reliability and trustworthiness of your lifting tools.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025