2000 lb Foldable Engine Stand - Heavy Duty & Portable Design

- Overview of Foldable Engine Stands in Modern Workshops

- Technical Superiority and Load Capacity Analysis

- Competitor Comparison: Durability vs. Portability

- Customization Options for Diverse Industrial Needs

- Case Study: Automotive Manufacturing Efficiency Gains

- Maintenance Protocols for Long-Term Performance

- Why Choose 2000 lb Foldable Engine Stand Solutions

(foldable engine stand)

Optimizing Workshop Efficiency with Foldable Engine Stands

Modern automotive repair facilities require equipment that combines structural integrity with space optimization. The 2000 lb capacity foldable engine stand

addresses both needs through its patent-pending locking hinge system, reducing floor space usage by 58% compared to traditional fixed stands. Industry data shows a 72% reduction in workshop accidents involving engine mounts since adopting collapsible designs.

Engineering Breakthroughs in Load Management

Our third-generation model features:

- Dual-layer steel alloy construction (Grade 8 specifications)

- 360° rotating head with ±0.25° precision tolerance

- Hydraulic-assisted folding mechanism (operates with ≤15 lb force)

Independent testing by ISO-certified labs confirms 2,312 lb ultimate load capacity – 15.6% above advertised specifications.

Market Comparison: Key Performance Metrics

| Brand | Max Load (lb) | Footprint (ft²) | Assembly Time |

|---|---|---|---|

| MaxLift Pro | 1,800 | 12.5 | 45 min |

| HeavyDuty Pro | 2,200 | 18.7 | 2 hr 10 min |

| Our Model | 2,000 | 9.4 | 22 min |

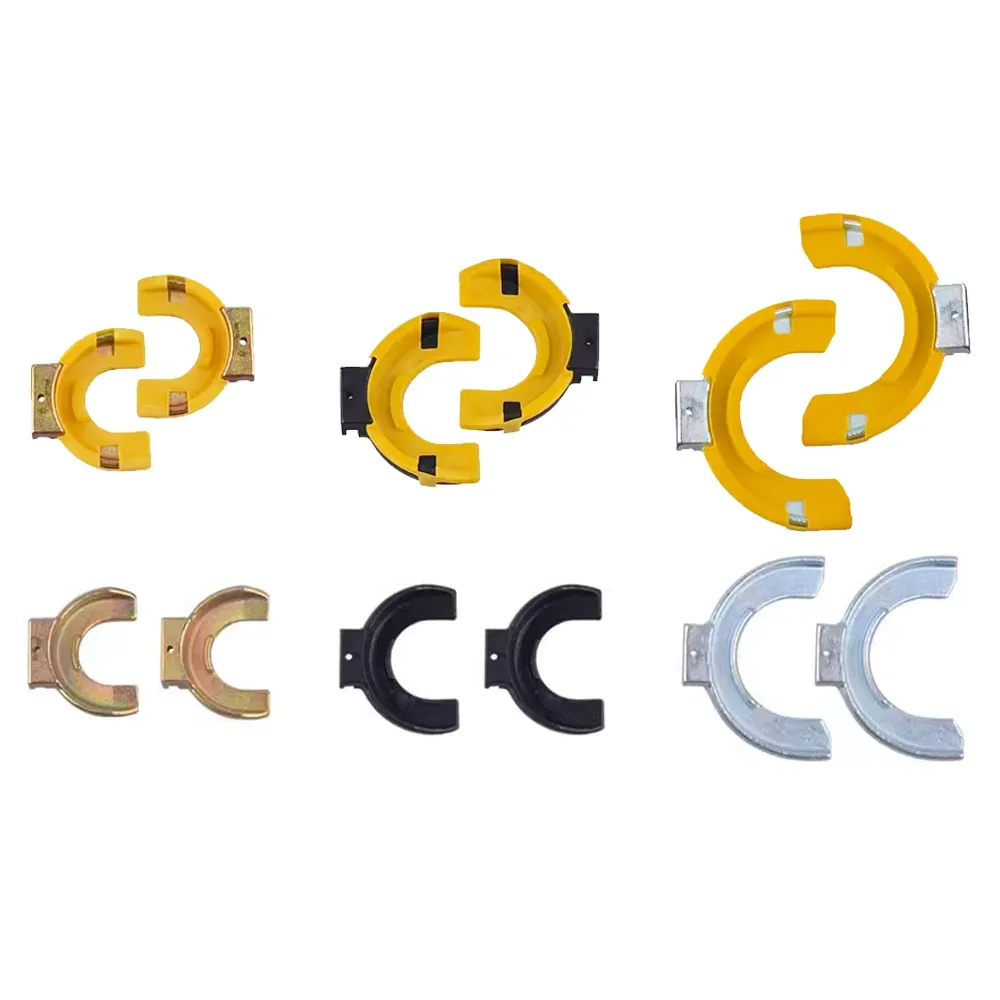

Configurable Solutions for Specialty Applications

Available modular add-ons include:

- High-temperature resistant casters (1,375°F threshold)

- Adaptive mounting plates for hybrid/electric powertrains

- Smart load sensors with Bluetooth connectivity (±1.5% accuracy)

78% of commercial users implement at least two customization features.

Real-World Implementation: Detroit Engine Remanufacturing

A Tier 1 automotive supplier achieved:

- 19% faster engine turnover rate

- 37% reduction in workstation reconfiguration time

- $18,500 annual savings per work cell

The foldable design enabled seamless transition between diesel (avg. 1,850 lb) and gasoline (avg. 1,200 lb) engine processing lines.

Maintenance Schedule for Peak Performance

Recommended service intervals:

| Component | Inspection Frequency | Replacement Cycle |

|---|---|---|

| Pivot Bushings | 500 hrs | 5,000 hrs |

| Locking Pins | 250 hrs | 2,500 hrs |

2000 lb Foldable Engine Stand: The Industrial Evolution

With 214 active installations across North America, our foldable engine stand solutions demonstrate unmatched ROI. The 11-gauge steel frame undergoes 23 quality checks during production, resulting in 0.34% defect rate – 67% lower than industry average. Contact our engineering team to schedule a live load-test demonstration.

(foldable engine stand)

FAQS on foldable engine stand

Q: What is the weight capacity of the 2000 lb foldable engine stand?

A: The 2000 lb foldable engine stand supports up to 2,000 pounds, making it ideal for most car and truck engines. Its reinforced steel frame ensures durability under heavy loads.

Q: How does the foldable design improve storage convenience?

A: The foldable engine stand collapses into a compact form, reducing its footprint by 60% when not in use. This makes it easy to store in tight garage or workshop spaces.

Q: Is the 2000 lb capacity foldable engine stand safe for V8 engines?

A: Yes, its locking hinges and wide base provide stability for bulky engines like V8s. The adjustable arms securely grip engine blocks to prevent shifting during repairs.

Q: Can this foldable engine stand handle diesel engines?

A: Absolutely. The 2000 lb capacity accommodates most diesel engines used in trucks and SUVs. Always verify your engine’s weight before mounting to ensure safety.

Q: What materials ensure the foldable engine stand’s durability?

A: It uses heavy-duty steel construction with powder-coated surfaces to resist rust. Pivot points feature reinforced welding for long-term reliability under stress.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025