High-Performance Automotive Scissor Jack for Heavy & Light Duty, Portable Use

Official Website: https://www.lgautotool.com

Email: jerry@longge-tools.com

Phone: +86 19322373413

Address: Xianxian County Longge Automobile Maintenance Tools Co., Ltd is located in the Hebei xianxian fantun industrial zone.

**Automotive Scissor Jack** is an indispensable tool in the automotive maintenance industry, serving a pivotal role for vehicle owners, repair professionals, and garage operators alike. With increasing demands for mobility and safety, the technology and applications surrounding the automotive scissor jack have evolved rapidly. This article delves into the latest industry trends, technical parameters, application scenarios, and comparative performance of heavy duty, light duty, and portable scissor jacks.

Industry Trends: The Evolution of Automotive Scissor Jack

Powered by technological innovation and stringent safety standards, the automotive scissor jack industry has witnessed notable advancements over the past decade. There is a clear shift from traditional, manual scissor jacks towards electric and hydraulic variants, though classic manual automotive scissor jack models remain popular due to their reliability and cost-efficiency.

With global vehicle ownership rising, especially in emerging economies (Statista Global Car Ownership Report), the need for versatile, lightweight, and heavy-duty jacking solutions increases. The application of high-strength steel, ergonomic design, and compliance with international safety standards (such as CE, GS, ANSI) underpins current industry developments (Auto Equipment Forum).

Technical Parameters: Comparative Table

Choosing the right automotive scissor jack depends on an understanding of key parameters like rated load, lifting range, material, portability, and safety mechanism. Below is a summarized table of commonly searched technical parameters across industry-leading jacks:

| Type | Rated Load | Lifting Range | Material | Weight | Portability | Application |

|---|---|---|---|---|---|---|

| Heavy Duty Scissor Jack | 2.0 - 3.5 tons | 100 - 450 mm | High-Strength Alloy Steel | 7 - 12 kg | Medium/Low | Trucks, SUVs |

| Light Duty Scissor Jack | 0.8 - 1.5 tons | 90 - 380 mm | Carbon Steel | 1.5 - 3 kg | High | Sedans, Small Cars |

| Portable Scissor Jack | 1.0 - 2.0 tons | 105 - 400 mm | High-Strength Steel | 2.2 - 4.5 kg | Very High | Roadside Emergency |

The above data represents a cross-section of specifications from market-leading brands and published engineering guidelines (SAE Technical Papers).

Company Product Overview: Car Lift Scissor Jack Steel Scissor Jacks Car Jack Portable

Xianxian County Longge Automobile Maintenance Tools Co., Ltd. is proud to offer the Car Lift Scissor Jack Steel Scissor Jacks Car Jack Portable. This product is engineered for exceptional performance in demanding automotive contexts.

- Uses & Applications: Primarily used for vehicle repairs, maintenance, and efficiently lifting light to medium loads. Essential for home garages, workshops, and emergency roadside assistance.

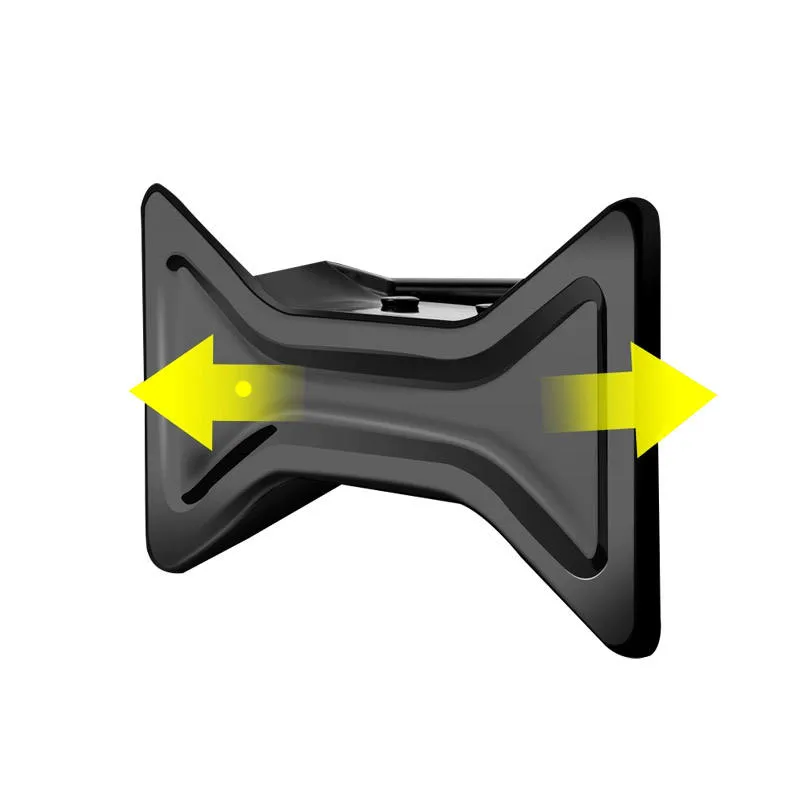

- Features: Enhanced load-bearing capacity (up to 2 tons), corrosion-resistant steel, precision screw mechanism for ease of operation, and reinforced safety locking.

- Reliability: Engineered with strict quality controls and international conformity.

- Design: Compact, portable, easy to store – the ideal portable scissor jack for professionals and everyday drivers.

Application Scenarios for Automotive Scissor Jack

Automotive scissor jacks are found in diverse settings, adapting to the dynamic needs of vehicle owners and professional repair shops:

- Emergency Roadside Assistance: Portable scissor jack models support quick tire changes and basic repairs outside the workshop.

- Professional Workshops: Heavy duty scissor jack variants facilitate maintenance of larger vehicles, including SUVs and light trucks, where lifting capacity is crucial.

- Home Garages: Light duty scissor jack options offer convenient self-maintenance for small cars and sedans, aligning with the DIY repairs trend.

- Industrial Fleets: Reliable, robust scissor jacks are integral in fleet management operations to reduce downtime.

Heavy Duty vs Light Duty vs Portable Scissor Jack

- Heavy Duty Scissor Jack: Designed for maximum load and stability to support larger vehicles. Ideal for commercial applications.

- Light Duty Scissor Jack: Lightweight and compact, suitable for standard consumer vehicles with emphasis on portability.

- Portable Scissor Jack: Strikes a balance between capacity and ease of transport; often included as standard equipment by OEMs.

- Decades of expertise in OEM/ODM automotive jacking solutions

- Full compliance with international safety and quality standards

- Robust R&D for continuous product optimization

- Global distribution and responsive after-sales service

View our automotive scissor jack range.

Expert FAQ: Key Terms and Technical Standards

- Q1: What is the primary material used in automotive scissor jacks?

- A: Most automotive scissor jack models use high-strength alloy steel due to its superior tensile properties and durability, ensuring safety during lifting operations.

- Q2: What are the industry standard load capacities?

- A: Common ratings are: light duty – 0.8~1.5 tons, portable – 1.0~2.0 tons, heavy duty – up to 3.5 tons, as defined by ANSI/ASME industry standards.

- Q3: Are scissor jacks compatible with all vehicles?

- A: Compatibility depends on ground clearance and jack points of the vehicle. Always match the jack's lifting range and load to your vehicle specifications.

- Q4: What safety mechanisms are included?

- A: Standard features include an anti-drop locking pin, load-limit screw, and wide base plate for enhanced stability, aligned with CE safety directives.

- Q5: What is the proper installation standard for scissor jacks?

- A: Installation must ensure flat and solid ground contact, aligning the jack saddle with designated lifting points (see ISO 16949:2023 standards).

- Q6: Is corrosion resistance important?

- A: Yes. Modern scissor jacks feature anti-corrosion coatings (e.g., powder coating, galvanization) to prolong service life, especially in humid or marine environments.

- Q7: How are technical parameters verified?

- A: Jacks undergo mechanical load testing, fatigue cycling, and international certification to ensure reliability across use scenarios (ResearchGate: Jack Strength Analysis).

EEAT Factors: Industry Authority and Reliability

- SAE International: Design and Analysis of Automotive Jacks

- Auto Equipment Forum: Evolution of Scissor Jacks in Automotive Industry

- ResearchGate: Automotive Jack Strength Analysis

- ASME Standards: American Lifting Devices – Code & Standards

- Statista: Automotive Industry Worldwide – Key Statistics

References: SAE International, Auto Equipment Forum, ResearchGate, ASME, Statista

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025