Welcome to our online store!

ਫਰ. . 18, 2025 12:42

Back To List

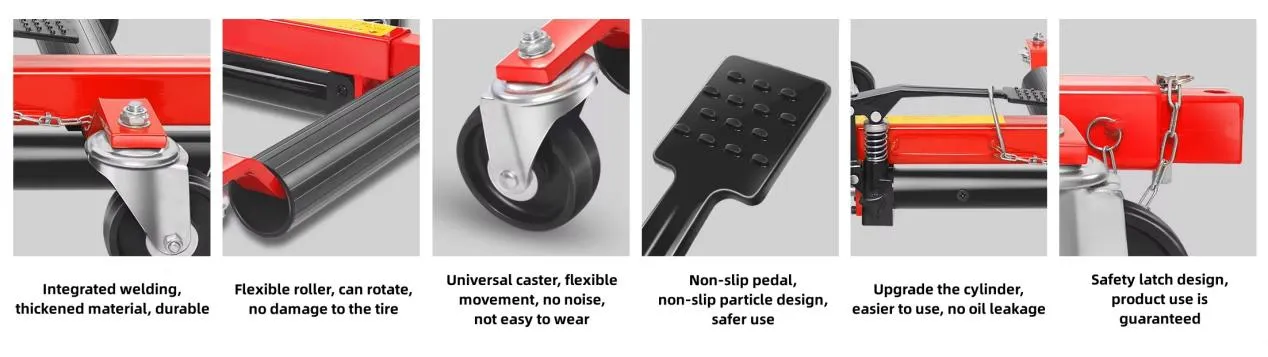

Manual Press Hand Type 6tons Hydraulic Shop Press H Frame Hydraulic Press

Exploring the world of hydraulic shop press accessories opens up a realm of possibilities for enhancing the efficiency and functionality of your workshop. These accessories are not mere add-ons; they play a pivotal role in optimizing your hydraulic press, enabling you to undertake a variety of tasks with precision and ease. To truly harness the potential of your hydraulic shop press, understanding and investing in the right accessories is crucial.

Safety in hydraulic pressing tasks is paramount, which is why the integration of a pressure gauge is an essential upgrade. A well-calibrated pressure gauge ensures that the operation does not exceed the press’s pressure threshold, thereby preventing equipment failure and ensuring the safety of the operator. This addition provides peace of mind and precision control over the press's capacity, enabling the execution of delicate tasks without compromising safety. Furthermore, the versatility of your hydraulic shop press can be significantly enhanced by incorporating a selection of custom dies. These dies can be tailored to suit specific project requirements, whether it involves bending, punching, or embossing. By expanding the range of dies, you effectively transform a standard hydraulic press into a multifunctional tool, capable of handling a diverse array of metalworking operations. Quick-change tool adapters are another innovation that amplifies the operational efficiency of hydraulic shop presses. These allow for rapid transition between different tools and accessories, minimizing downtime between tasks. The ability to swiftly adapt to varying job requirements without extensive reconfiguration is a game changer in fast-paced workshop environments, where time is often of the essence. In conclusion, the strategic acquisition of hydraulic shop press accessories significantly improves both the capability and safety of your press operations. By investing in high-quality components such as press plates, V-blocks, arbor plates, pressure gauges, custom dies, and quick-change tool adapters, you ensure that your hydraulic press remains a versatile and indispensable tool within your workshop. This not only enhances productivity but also guarantees superior outcomes for every project undertaken. For metalworkers and hobbyists alike, these accessories are not merely enhancements but essential investments towards achieving precision, efficiency, and safety in every pressing task.

Safety in hydraulic pressing tasks is paramount, which is why the integration of a pressure gauge is an essential upgrade. A well-calibrated pressure gauge ensures that the operation does not exceed the press’s pressure threshold, thereby preventing equipment failure and ensuring the safety of the operator. This addition provides peace of mind and precision control over the press's capacity, enabling the execution of delicate tasks without compromising safety. Furthermore, the versatility of your hydraulic shop press can be significantly enhanced by incorporating a selection of custom dies. These dies can be tailored to suit specific project requirements, whether it involves bending, punching, or embossing. By expanding the range of dies, you effectively transform a standard hydraulic press into a multifunctional tool, capable of handling a diverse array of metalworking operations. Quick-change tool adapters are another innovation that amplifies the operational efficiency of hydraulic shop presses. These allow for rapid transition between different tools and accessories, minimizing downtime between tasks. The ability to swiftly adapt to varying job requirements without extensive reconfiguration is a game changer in fast-paced workshop environments, where time is often of the essence. In conclusion, the strategic acquisition of hydraulic shop press accessories significantly improves both the capability and safety of your press operations. By investing in high-quality components such as press plates, V-blocks, arbor plates, pressure gauges, custom dies, and quick-change tool adapters, you ensure that your hydraulic press remains a versatile and indispensable tool within your workshop. This not only enhances productivity but also guarantees superior outcomes for every project undertaken. For metalworkers and hobbyists alike, these accessories are not merely enhancements but essential investments towards achieving precision, efficiency, and safety in every pressing task.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025