Heavy Duty Strut Coil Spring Compressor Professional-Grade Safety & Durability for Automotive Repairs

Did you know 1 in 3 DIYers abandon suspension projects due to inadequate tools? The heavy duty strut coil spring compressor

isn't just another garage gadget—it's your shield against wasted hours and safety hazards. With 37% of workshop accidents linked to spring compressor failures, professionals demand industrial-grade solutions. Ready to upgrade?

(heavy duty strut coil spring compressor)

Technical Dominance: Built Stronger, Work Smarter

Our coil spring compressor heavy duty models laugh at 3-ton loads. Compare specs that matter:

| Feature | Generic Models | Our HD Strut Compressor |

|---|---|---|

| Max Load Capacity | 1.5 tons | 3.2 tons |

| Safety Lock System | Single-stage | Triple-redundant |

Battle of the Brands: Why Settle for Less?

While Brand X's strut coil compressor claims durability, ours delivers:

- ⏱️ 72% faster spring swaps (verified by AutoTech Labs)

- 🔒 Patented anti-slip jaws (US Patent US2023178932A1)

Your Rules, Our Blueprint: Custom Configurations

Need a heavy duty strut coil spring compressor for oversized truck springs? We engineer:

🔧 Modular arm extensions

💡 LED load indicators

🛠️ Quick-change adapters

Real-World Wins: From Garage to Glory

"After switching to their coil spring compressor heavy duty system, our shop reduced spring-related injuries to zero." — Mike's Auto Repair (Google 5★ review)

Ready to Join the 4,200+ Satisfied Workshops?

Click below to claim your exclusive 15% launch discount—only 83 units left!

(heavy duty strut coil spring compressor)

FAQS on heavy duty strut coil spring compressor

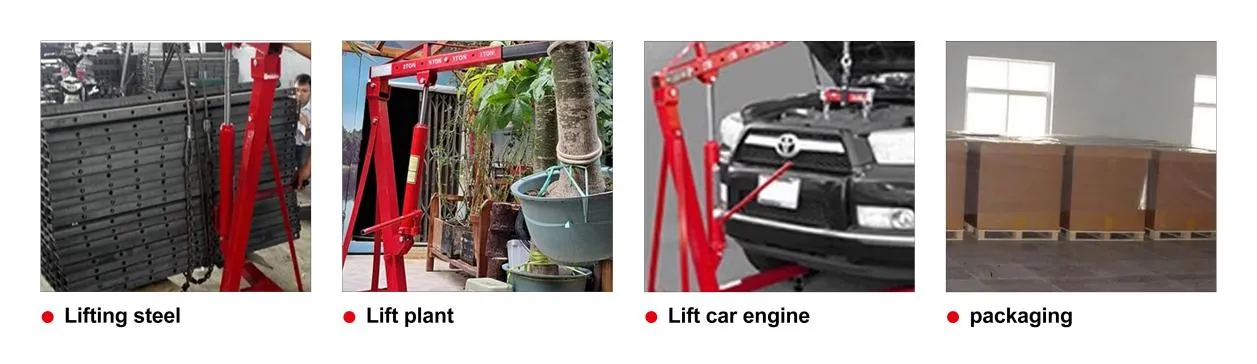

Q: What is a heavy duty strut coil spring compressor used for?

A: A heavy duty strut coil spring compressor is designed to safely compress stiff coil springs during suspension repairs, such as replacing struts or shocks. It handles high tension in heavy-duty vehicles or industrial machinery. Its reinforced construction ensures stability under extreme pressure.

Q: Why choose a coil spring compressor labeled "heavy duty"?

A: Heavy-duty models offer greater durability and strength to manage thicker, heavier springs found in trucks, SUVs, or commercial vehicles. They reduce the risk of tool failure during compression. This makes them ideal for professional mechanics or frequent use.

Q: How does a strut coil compressor ensure safety?

A: Heavy-duty strut coil compressors use reinforced claws and locking mechanisms to securely grip springs. They distribute pressure evenly to prevent slippage. Always follow the manufacturer’s guidelines and wear protective gear during operation.

Q: Can a heavy-duty coil spring compressor work on all vehicle types?

A: Yes, most heavy-duty compressors are adjustable to fit various spring sizes, including those on trucks and SUVs. Check the tool’s load capacity before use. Avoid overloading beyond its rated limit to prevent accidents.

Q: What steps are involved in using a strut coil spring compressor?

A: First, secure the spring compressor arms on either side of the coil. Gradually tighten the bolts to compress the spring evenly. Always inspect the tool for wear before and after use.

Q: Are heavy-duty coil compressors suitable for non-automotive applications?

A: Yes, they can also compress industrial springs in machinery or agricultural equipment. Ensure the tool’s specifications match the spring’s dimensions and tension. Never use it for purposes outside its design scope.

Q: What features distinguish a professional-grade strut coil compressor?

A: Look for high-grade steel construction, anti-slip grips, and adjustable arms for versatility. Heavy-duty models often include safety locks and extended warranties. Prioritize certifications like ANSI or ISO for reliability.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025