Welcome to our online store!

Februari . 16, 2025 07:23

Back To List

2 post lift car lift

Drywall panel lifts, indispensable in the realm of construction and home renovation, offer an unparalleled solution to the challenges of lifting and positioning drywall sheets. These lifts are not merely tools but an embodiment of engineering expertise designed to enhance efficiency, safety, and precision.

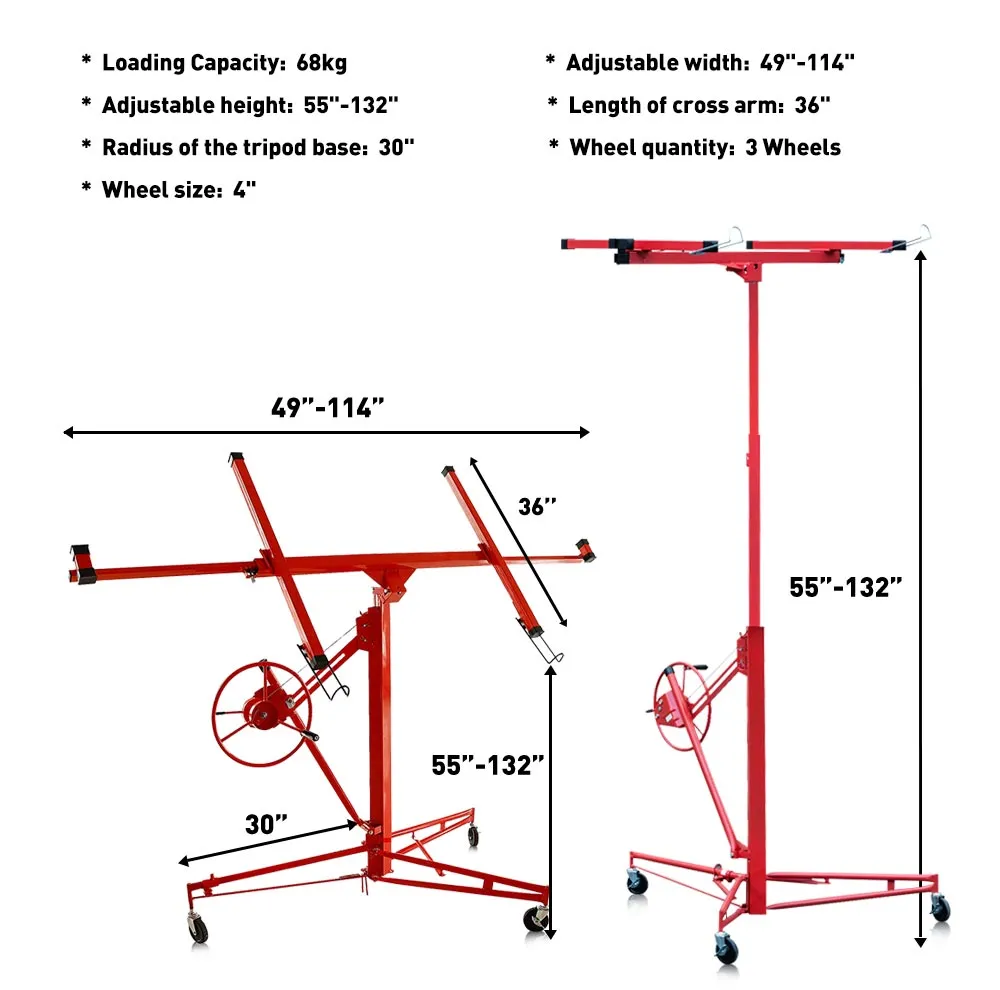

Trustworthiness is another pivotal consideration associated with the use of drywall panel lifts. Reputable brands ensure their products are manufactured to the highest standards, adhering to stringent safety regulations. This assurance is crucial in minimizing workplace accidents and injuries. Users often share testimonials and reviews that detail their experiences with specific models of drywall lifts, providing prospective buyers with insights into the products' reliability and durability. These endorsements are valuable resources for users seeking to invest in trustworthy equipment that delivers on its promises. For individuals and businesses contemplating the acquisition of a drywall panel lift, it's advisable to assess several factors. Key among these is the specific lifting capacity required, as drywall sheets come in varying sizes and weights. Additionally, the maximum lift height needed is crucial, especially for projects involving high ceilings or multi-level constructions. Armed with the right equipment specifications, users can make informed decisions that best suit their project demands. In conclusion, drywall panel lifts represent a fusion of engineering ingenuity and practical application, addressing the core needs of safety, efficiency, and precision in construction. By investing in a quality drywall lift, users not only ensure a smoother project timeline but also contribute to a safe and more productive working environment. Embracing this advanced tool within construction practices not only reflects a commitment to modernity but also to the values of expertise, authority, and trust. As the industry continues to evolve, so too will the innovations enhancing the functionality and reliability of drywall panel lifts, cementing their place as a cornerstone of modern building practices.

Trustworthiness is another pivotal consideration associated with the use of drywall panel lifts. Reputable brands ensure their products are manufactured to the highest standards, adhering to stringent safety regulations. This assurance is crucial in minimizing workplace accidents and injuries. Users often share testimonials and reviews that detail their experiences with specific models of drywall lifts, providing prospective buyers with insights into the products' reliability and durability. These endorsements are valuable resources for users seeking to invest in trustworthy equipment that delivers on its promises. For individuals and businesses contemplating the acquisition of a drywall panel lift, it's advisable to assess several factors. Key among these is the specific lifting capacity required, as drywall sheets come in varying sizes and weights. Additionally, the maximum lift height needed is crucial, especially for projects involving high ceilings or multi-level constructions. Armed with the right equipment specifications, users can make informed decisions that best suit their project demands. In conclusion, drywall panel lifts represent a fusion of engineering ingenuity and practical application, addressing the core needs of safety, efficiency, and precision in construction. By investing in a quality drywall lift, users not only ensure a smoother project timeline but also contribute to a safe and more productive working environment. Embracing this advanced tool within construction practices not only reflects a commitment to modernity but also to the values of expertise, authority, and trust. As the industry continues to evolve, so too will the innovations enhancing the functionality and reliability of drywall panel lifts, cementing their place as a cornerstone of modern building practices.

Prev:

Next:

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025