Welcome to our online store!

2月 . 20, 2025 11:05

Back To List

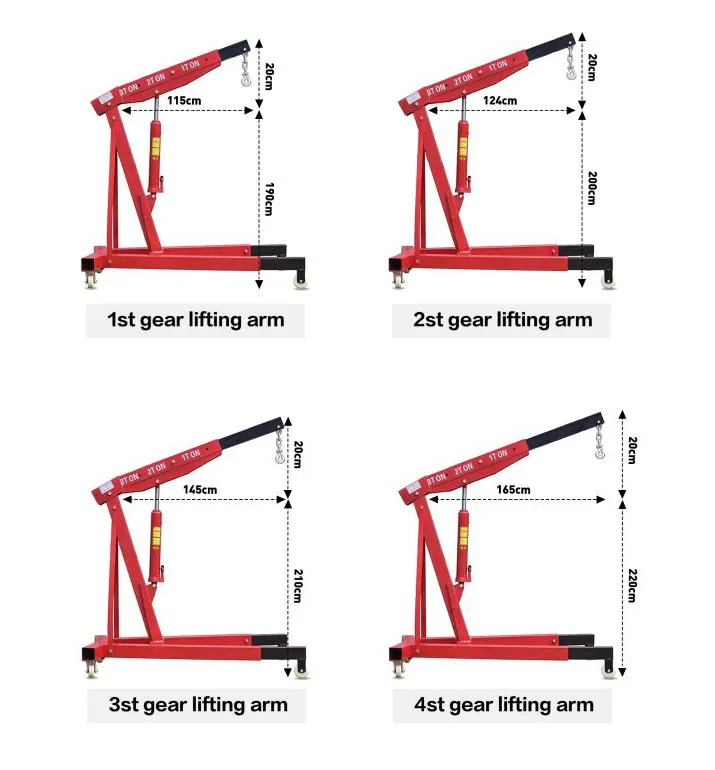

2 Ton Folding Shop Crane Lifting Machine Mini Truck Hydraulic Jack Engine Crane Folding Crane

A hydraulic jack press is a versatile tool that has become indispensable in industries ranging from automotive to manufacturing. Known for its power and precision, the hydraulic jack press utilizes the principles of fluid mechanics to lift, press, and manipulate heavy loads with ease. At the heart of its functionality lies the mechanism of hydraulic pressure, where fluid is compressed, creating a force capable of lifting loads far heavier than the implement itself. This tool isn't just about brute force; it's about delivering that force with precision, making it an essential part of any workshop or production line.

The hydraulic jack press's flexibility extends its application far beyond lifting objects. Its ability to exert controlled pressure makes it ideal for tasks like bending rigid materials, straightening parts, or assembling and disassembling tight components. Depending on the attachment used, a hydraulic press can perform an extensive range of functions, proving its authority as a multifaceted tool in any industrial toolkit. This adaptability makes it a cost-effective solution, as one machine can perform multiple tasks, reducing the need for numerous different devices. In terms of expertise, the utility of a hydraulic jack press demands a basic understanding of hydraulic systems and pressure mechanics. Trained operators can maximize the tool's potential by understanding how differential pressure and fluid dynamics work together to deliver performance. Investing in training and understanding machine limits and capabilities is vital in ensuring long-term operational efficiency and safety. Proper use and maintenance, including regular oil checks and inspections, extend the machine's life and uphold industry standards of reliability. For anyone considering the acquisition of a hydraulic jack press, it's essential to consider the specific requirements of their operations. Factors such as the load capacity, operational environment, and specific tasks dictate which model or type is most appropriate. Consulting with manufacturers or industry experts helps ensure the chosen hydraulic jack press meets the unique demands of the business, cementing its role in achieving operational excellence. The technology behind hydraulic jack presses has evolved, with recent innovations focusing on enhancing efficiency and sustainability. Advances such as energy-efficient systems and the use of eco-friendly hydraulic fluids underscore the industry's commitment to sustainable practices, aligning with global efforts to minimize environmental impact. These advances position hydraulic jack presses not only as tools of great power and utility but also as components of a forward-thinking approach to industrial solutions.

The hydraulic jack press's flexibility extends its application far beyond lifting objects. Its ability to exert controlled pressure makes it ideal for tasks like bending rigid materials, straightening parts, or assembling and disassembling tight components. Depending on the attachment used, a hydraulic press can perform an extensive range of functions, proving its authority as a multifaceted tool in any industrial toolkit. This adaptability makes it a cost-effective solution, as one machine can perform multiple tasks, reducing the need for numerous different devices. In terms of expertise, the utility of a hydraulic jack press demands a basic understanding of hydraulic systems and pressure mechanics. Trained operators can maximize the tool's potential by understanding how differential pressure and fluid dynamics work together to deliver performance. Investing in training and understanding machine limits and capabilities is vital in ensuring long-term operational efficiency and safety. Proper use and maintenance, including regular oil checks and inspections, extend the machine's life and uphold industry standards of reliability. For anyone considering the acquisition of a hydraulic jack press, it's essential to consider the specific requirements of their operations. Factors such as the load capacity, operational environment, and specific tasks dictate which model or type is most appropriate. Consulting with manufacturers or industry experts helps ensure the chosen hydraulic jack press meets the unique demands of the business, cementing its role in achieving operational excellence. The technology behind hydraulic jack presses has evolved, with recent innovations focusing on enhancing efficiency and sustainability. Advances such as energy-efficient systems and the use of eco-friendly hydraulic fluids underscore the industry's commitment to sustainable practices, aligning with global efforts to minimize environmental impact. These advances position hydraulic jack presses not only as tools of great power and utility but also as components of a forward-thinking approach to industrial solutions.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025