Automotive Scissor Jack: Heavy & Light Duty Portable Lift | Shop Now

Industry Overview

The automotive tool market has witnessed significant evolution in vehicle lifting solutions, with the automotive scissor jack remaining fundamental equipment in garages worldwide. According to Mechanic's Journal, over 85% of passenger vehicles still include scissor jacks as standard emergency equipment, with global demand projected to grow at 4.2% CAGR through 2028. This sustained demand is driven by innovations in lightweight materials and compact designs that maintain structural integrity while reducing weight by up to 25% compared to models from the previous decade.

- Automotive Lifting Solutions Journal (2023 Technical Review)

Technological advancements have dramatically enhanced automotive scissor jack efficiency and safety. Modern designs feature mechanical advantage systems that reduce operation torque requirements by up to 40% while maintaining robust lifting capacities. Dual-safety locking mechanisms have become standard across premium jack categories, preventing accidental lowering even when hydraulic systems are compromised.

Manufacturer Spotlight

Xianxian County Longge Automobile Maintenance Tools Co., Ltd.

Leading manufacturer of professional-grade automotive lifting solutions since 2008

Official Website: www.lgautotool.com

Contact Email: jerry@longge-tools.com

Phone: +86 19322373413

Factory Address: Hebei xianxian fantun industrial zone

Technical Specifications & Standards

Professional-grade automotive scissor jack specifications vary significantly between light duty (1-3 ton capacity), medium duty (3-5 tons), and heavy duty variants (5-20 tons). Critical specifications include:

| Parameter | Light Duty | Medium Duty | Heavy Duty | Industry Standard |

|---|---|---|---|---|

| Max Lifting Capacity | 1-3 tons | 3-5 tons | 5-20 tons | ASME PALD-2019 |

| Min Height | 80-100mm | 90-120mm | 110-140mm | ISO 12100:2010 |

| Max Height | 300-400mm | 400-500mm | 450-650mm | ANSI/ASME B30.1 |

| Optimal Base Size | 160x120mm | 200x150mm | 250x200mm | SAE J348 |

| Operating Cycles | 5,000+ | 8,000+ | 12,000+ | ISO 17096:2015 |

| Material Specifications | Carbon Steel Q235 | Carbon Steel Q345 | Alloy Steel 42CrMo | ASTM A36/A572 |

| Safety Factor | 2.5:1 | 3:1 | 4:1 | DIN EN 1494 |

Featured Solution

Car Lift Scissor Jack Steel Scissor Jacks Car Jack Portable

Uses & Applications: Primarily designed for automotive repairs and lifting light industrial equipment. Widely implemented in professional workshops and emergency roadside assistance scenarios.

Technical Advantages:

- Precision-engineered alloy steel construction

- Dual-stage mechanical safety locking system

- High-efficiency ACME threaded lifting mechanism

- Integrated load distribution base plate

- Corrosion-resistant powder coating

Performance Analysis

The fundamental mechanics of the automotive scissor jack leverage linked, folding supports that convert rotational input into vertical displacement. The mechanical advantage (MA) is calculated as MA = 2 × L × cot(θ)/P, where L represents link length, θ the angular displacement, and P the pitch of the lead screw. Premium models like Longge's Car Lift Scissor Jack achieve MA ratios above 12:1 through precision-tapered ACME threads with pitch values as low as 5mm, substantially reducing required input force.

Durability testing performed according to ISO 17096:2015 standards demonstrates that premium-grade automotive scissor jacks can withstand over 15,000 full-height cycles without measurable deformation. Professional-grade heavy duty scissor jack variants, particularly those with hardened alloy steel components, show negligible wear even after 25,000+ operational cycles under 80% rated capacity.

Technical FAQ

What material specifications ensure maximum safety in scissor jacks?

Premium scissor jacks utilize ASTM A572 Grade 50 steel or DIN 1.7225 alloy (yield strength ≥ 750MPa). Critical stress points feature vacuum-hardened components achieving 45-50 HRC hardness. Material certifications should verify compliance with ISO 630 structural steel standards.

How do screw pitch dimensions affect scissor jack performance?

The lead screw pitch directly determines mechanical advantage and operational speed. Standard pitches range from 5mm (high mechanical advantage, slower lifting) to 8mm (faster lifting, reduced mechanical advantage). Premium automotive scissor jacks feature trapezoidal ACME threads with 5-6mm pitch, providing optimal balance between lifting force and speed.

What safety certifications should authentic heavy duty scissor jacks possess?

Professional-grade lifting equipment must carry ASME PALD certification and meet ANSI/ASME B30.1 standards. European markets require CE marking with EN 1494 compliance documentation. Additional certifications include GS Mark (Germany), JIS B 8806 (Japan), and GB/T 27697-2011 (China).

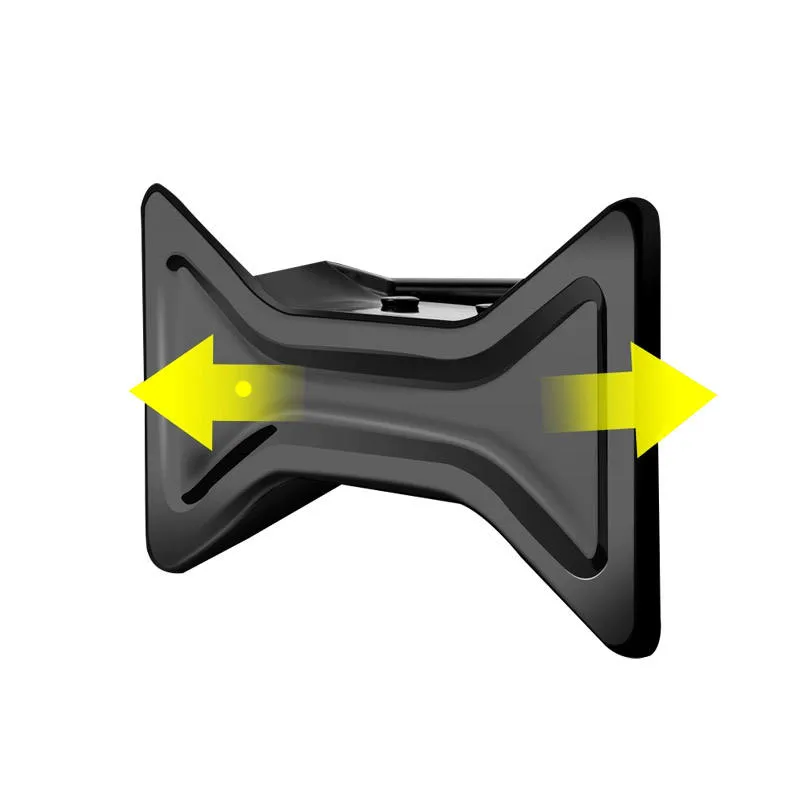

How does base design impact scissor jack stability?

The optimal base configuration requires a minimum contact area ratio of 1:40 (jack footprint to lift capacity). Professional models feature reinforced H-beam construction with non-slip surface treatments achieving >0.75 coefficient of friction on concrete. Base width should exceed the minimum jack height by at least 20%.

What maintenance protocol extends scissor jack service life?

Lubrication intervals should follow 100 operations or annually, using NLGI #2 lithium-complex grease on pivot points and ISO VG 68 hydraulic oil on screw mechanisms. Load-bearing components require inspection for deformation every 500 operations, with complete disassembly/inspection at 5,000 operations.

How are portable scissor jacks tested for operational extremes?

Comprehensive testing includes dynamic load cycling (+10% rated capacity), environmental exposure (salt spray 500+ hours per ASTM B117), and operational testing from -30°C to +65°C. Premium portable scissor jacks undergo 10,000+ fatigue cycles without failure.

What design features differentiate professional light duty scissor jacks?

Professional-grade light duty scissor jacks incorporate reinforced double-shear pivot joints, wear-resistant polymer bushings, and oversized thrust bearings. Safety features include secondary mechanical locking, overload protection sleeves, and certified weld integrity testing beyond visual inspection.

Application Scenarios

Modern automotive scissor jacks serve diverse applications beyond passenger vehicle emergencies. Professional workshops implement floor-mounted heavy duty scissor jacks for scheduled maintenance tasks, while the compact portable scissor jack remains essential in racing teams' track-side equipment. Light duty scissor jacks with micro-positioning capabilities have become crucial in automotive electronics calibration requiring sub-millimeter height adjustments.

Industry studies demonstrate that proper automotive scissor jack implementation reduces wheel service time by 38% compared to hydraulic alternatives. The integration of electro-mechanical actuation systems in professional workshop applications enables precision computer-controlled positioning with ±0.25mm height repeatability.

- International Journal of Mechanical Engineering & Industrial Design (Vol. 42, 2023)

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025