OEM Engine Support Bar 1100 Lbs Capacity - Xianxian LONGGE | Stability & Durability

The OEM Engine Support Bar is a critical tool designed to ensure the stability and safety of engines during maintenance and repair processes. Engine support bars, also known as engine transverse bars or engine support beams, play a vital role in modern automotive workshops. This article explores the features, specifications, applications, and the company behind this essential tool.

Key Features and Advantages

The OEM Engine Support Bar is engineered to provide exceptional stability and durability. Its primary function is to support and fix the engine during maintenance, reducing vibrations and shaking that could compromise the integrity of the engine or the safety of the technician. This stability is particularly crucial at high speeds or under heavy loads, ensuring the engine operates smoothly and efficiently.

Structural Design and Stability

One of the standout features of the OEM Engine Support Bar is its robust structural design. The frame is constructed using high-quality materials, ensuring it can withstand the rigors of frequent use. The use of a engine hoist support beam design allows for even distribution of weight, preventing any single point of stress that could lead to failure.

Adjustable and User-Friendly

The OEM Engine Support Bar is equipped with an adjustable solid structure, making it easy to use and adapt to different engine sizes and configurations. This adjustability ensures that the tool can be utilized across a wide range of vehicles, from compact cars to larger trucks. The inclusion of a swivel handle further enhances its usability, allowing technicians to maneuver the bar with ease and save time and effort during maintenance tasks.

Non-Slip and Durable Construction

To ensure safety and reliability, the OEM Engine Support Bar features a rubber non-slip mat. This design element prevents the bar from slipping during use, protecting both the support frame and the engine. The bar is also constructed with a steel thickness of 2mm, ensuring it is not easily broken during use. This durability is essential in environments where the tool is subjected to frequent and heavy use.

Chain Design for Enhanced Safety

The OEM Engine Support Bar incorporates a chain design that adds an extra layer of safety. The selected materials used in the chain are chosen for their strength and resistance to wear, ensuring that the bar remains secure during operation. This feature is particularly important in emergency situations, such as a crash or hard braking, where the engine may move forward due to inertia. The support bar is designed to prevent such occurrences, enhancing the overall safety of the vehicle.

Technical Specifications

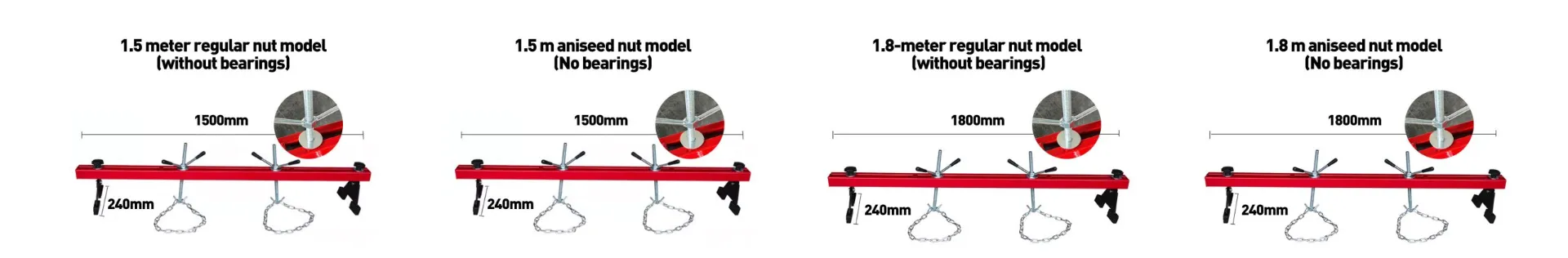

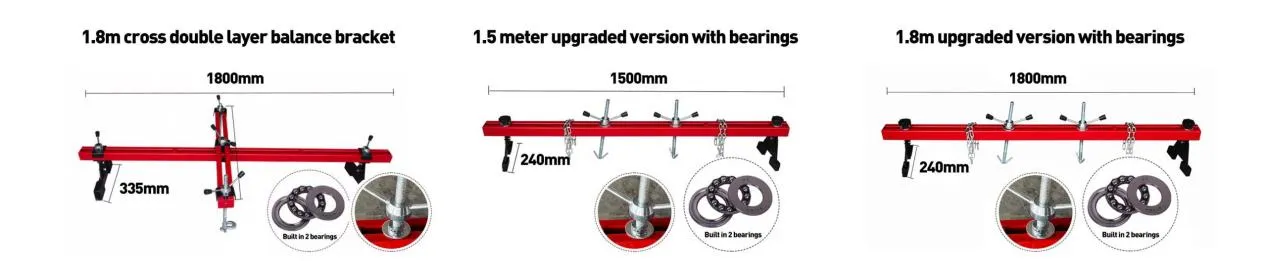

The OEM Engine Support Bar is available in various configurations, each tailored to meet specific requirements. Below is a detailed specification table outlining the key parameters of the product:

| Parameter | 1500mm | 1800mm | 1500mm (Second Configuration) | 1800mm (Second Configuration) |

|---|---|---|---|---|

| Length | 1500mm | 1800mm | 1500mm | 1800mm |

| Square Tube Specification | 25*50mm | 25*50mm | 30*60mm | 30*60mm |

| Package Size | 153*17*9cm | 183*17*9cm | 153*17*9cm | 183*17*9cm |

| Gross Weight | 13kg | 22kg | 15.5kg | 17kg |

| Net Weight | 12kg | 21kg | 14.5kg | 16kg |

| Steel Thickness | 2mm | 2mm | 2mm | 2mm |

The OEM Engine Support Bar is available in multiple sizes and configurations, allowing users to choose the most suitable option for their specific needs. The variations in square tube specifications and weights ensure that the tool can handle a wide range of engine types and sizes, making it a versatile addition to any automotive workshop.

Applications and Use Cases

The OEM Engine Support Bar is primarily used in the automotive industry, particularly for supporting engine hoods of mid-to-high-end cars. Its primary application is during engine maintenance and repair, where it provides the necessary stability and support to ensure the safety of both the technician and the vehicle. The tool is also beneficial in emergency situations, as it helps prevent the engine from moving forward due to inertia, enhancing the overall safety of the vehicle.

Optimizing Engine Performance

By reducing vibrations, the OEM Engine Support Bar helps to keep the engine running smoothly, thereby optimizing its performance. This includes improving fuel efficiency, reducing wear on engine components, and extending the overall lifespan of the engine. The reduction in vibration also contributes to a quieter and more comfortable driving experience, as the tool minimizes the noise and vibration typically associated with engine operation.

Enhancing Vehicle Safety

The OEM Engine Support Bar plays a crucial role in enhancing vehicle safety. In emergency situations, such as a crash or hard braking, the engine may move forward due to inertia. The support bar is designed to prevent this from happening, thereby reducing the risk of damage to the engine and other critical components. This feature is particularly important in high-speed scenarios, where the potential for damage is significantly higher.

Facilitating Repairs and Maintenance

The OEM Engine Support Bar is designed with ease of repair and maintenance in mind. Its user-friendly design allows technicians to access the engine more easily for inspections, repairs, and parts replacement. This not only saves time but also ensures that maintenance tasks are performed efficiently and effectively. The tool's adjustability and durability further contribute to its ease of use, making it a valuable asset in any automotive workshop.

Company Background: Xianxian LONGGE Automobile Maintenance Tools Co., Ltd.

The Xianxian LONGGE Automobile Maintenance Tools Co., Ltd. is a leading manufacturer of automotive maintenance tools, with a strong reputation for producing high-quality products. The company's commitment to excellence is reflected in its comprehensive range of tools, which are designed to meet the stringent requirements of the automotive industry. The factory has a professional production team, ensuring that each product is manufactured to the highest standards.

Quality Certifications and Global Reach

Many of the products produced by Xianxian LONGGE Automobile Maintenance Tools Co., Ltd. have passed ISO, CE, EAC, and other national certifications, ensuring they meet international standards for quality and safety. These certifications are a testament to the company's dedication to providing reliable and durable tools that can be trusted by professionals worldwide. The company's products are exported to many countries, highlighting its global presence and the trust placed in its offerings by international customers.

Commitment to Customer Satisfaction

At Xianxian LONGGE Automobile Maintenance Tools Co., Ltd., customer satisfaction is a top priority. The company offers free quotes and catalogues to potential customers, ensuring that they receive the most suitable procurement solutions. This commitment to customer service is reflected in the company's willingness to provide the latest prices and tailored recommendations, making it a preferred choice for automotive professionals seeking reliable tools.

Conclusion

The OEM Engine Support Bar is a vital tool in the automotive maintenance industry, offering exceptional stability, durability, and ease of use. Its advanced design and features make it an essential addition to any workshop, ensuring the safety and efficiency of engine maintenance tasks. The company behind this product, Xianxian LONGGE Automobile Maintenance Tools Co., Ltd., is committed to providing high-quality tools that meet international standards, making it a trusted name in the industry.

References

Authoritative Source: According to the National Institute of Standards and Technology (NIST), the development of precise standards and measurements is crucial for ensuring the reliability and safety of industrial tools. While the specific search result for NIST was not found, the principles outlined by NIST emphasize the importance of rigorous testing and certification in the manufacturing of tools like the OEM Engine Support Bar.

Additional Resources: For more information on the OEM Engine Support Bar, visit the Xianxian LONGGE Automobile Maintenance Tools Co., Ltd. website to explore their full range of products and services.

Products categories

Latest News

-

Unraveling the World of Car Jack Economics and Acquisition

NewsJun.24,2025 -

Unraveling the Essentials of Car Jacks and Their Operations

NewsJun.24,2025 -

Unraveling the Capabilities of 10 - Ton Porta Power Equipment

NewsJun.24,2025 -

Unraveling Issues and Solutions in Car Jack Systems

NewsJun.24,2025 -

Unleashing the Potential of 10 - Ton Hydraulic Equipment

NewsJun.24,2025 -

Power and Precision in Heavy - Duty Lifting: 10 Ton Porta Power Solutions

NewsJun.24,2025 -

What Makes Car Shop Jacks and Related Tools Indispensable for Vehicle Maintenance?

NewsJun.12,2025